Login / Signup

Cart

Your cart is empty

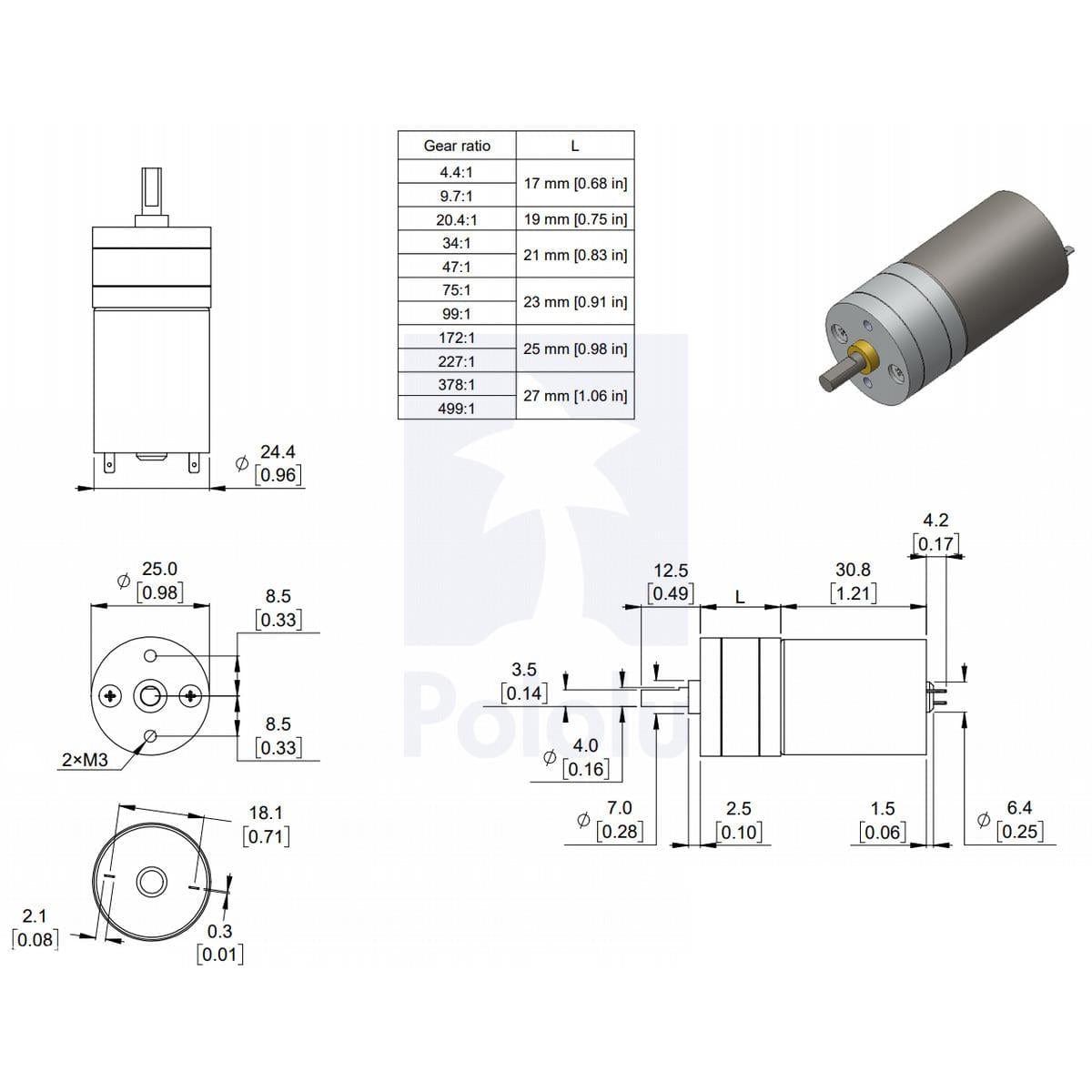

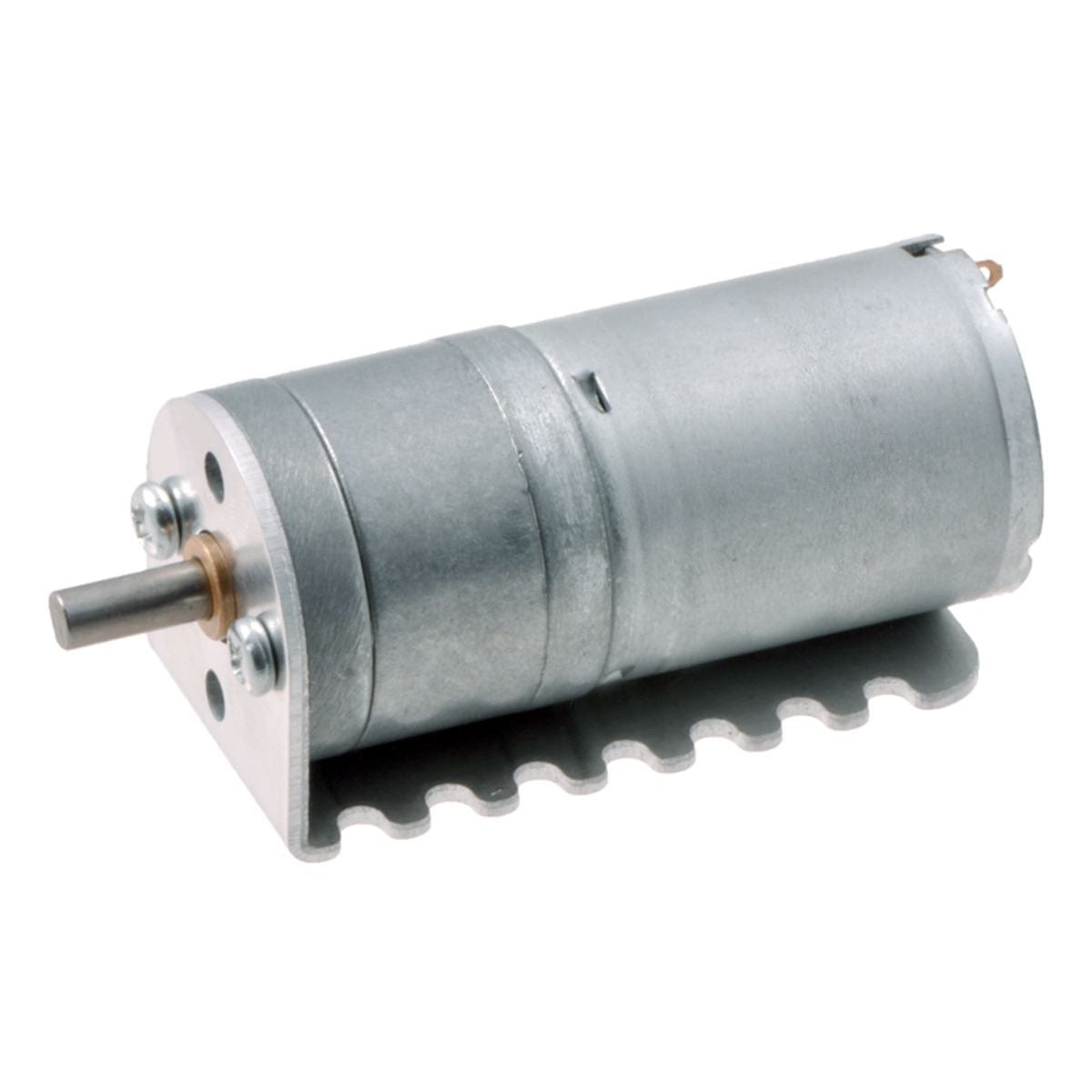

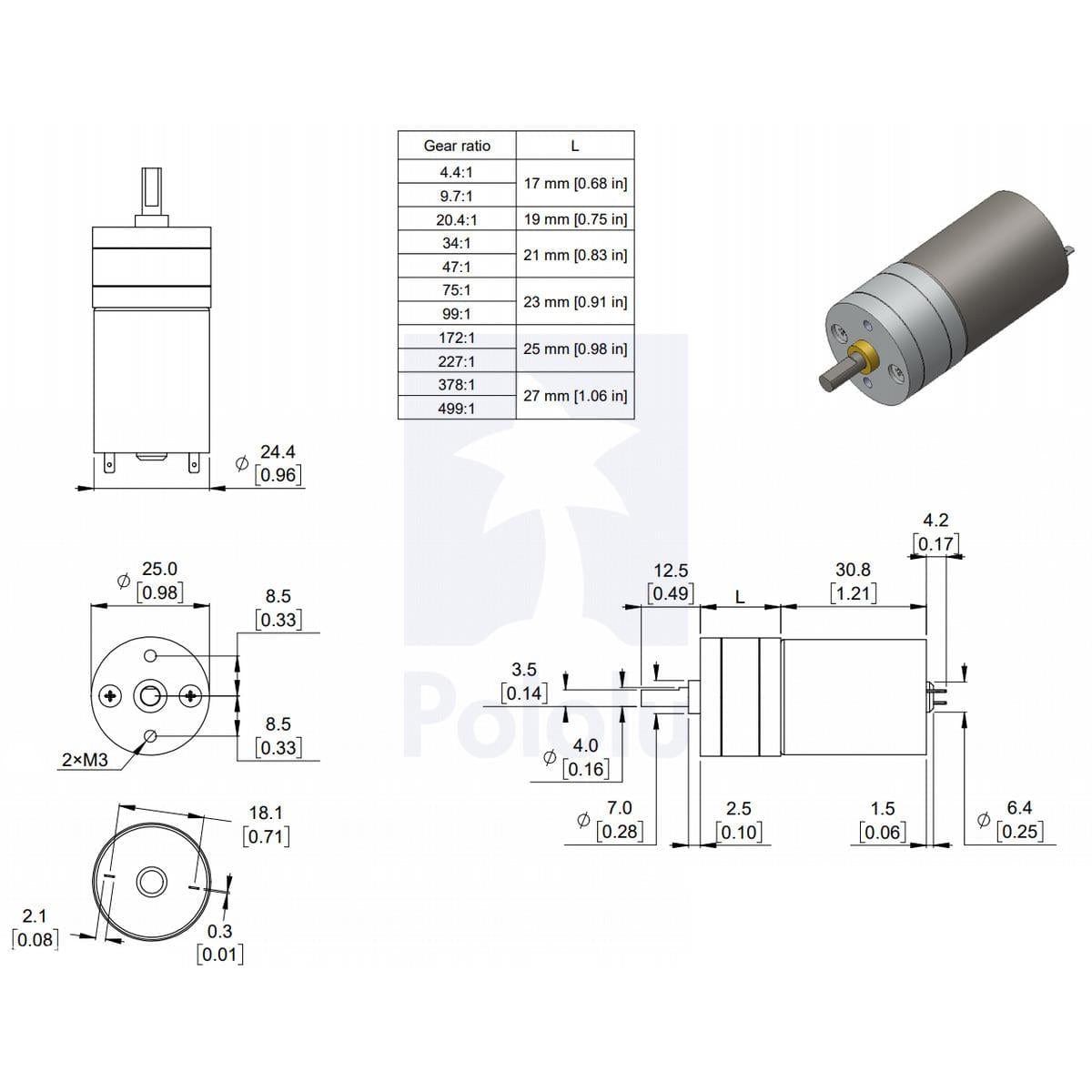

This Pololu 25D gearmotor consists of a medium-power, 12V brushed DC motor combined with a 99:1 (98.78:1) metal spur gearbox. The gearmotor is cylindrical, with a diameter just under 25mm, and the D-shaped output shaft is 4mm in diameter and extends 12.5mm from the faceplate of the gearbox.

In general, these kinds of motors can run at voltages above and below their nominal voltages (they can begin rotating at voltages as low as 1V); lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor. This motor will run at 6V but is intended for operation at 12V.

We also stock low-power and high-power versions of this motor. You can find our entire range of motors here.

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The listed stall torques and currents are theoretical extrapolations; units will typically stall well before these points as the motors heat up. The recommended upper limit for continuously applied loads is 4 kg⋅cm (55 oz⋅in), and the recommended upper limit for intermittently permissible torque is 8 kg⋅cm (110 oz⋅in). Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

| Voltage | 12V |

| Version | Medium Power |

| Gear ratio | 98.78:1 |

| No-load speed @ 12V | 79 rpm |

| No-load current @ 12V | 0.080A |

| Stall current @ 12V | 1.8A |

| Stall torque @ 12V | 11 kg·cm |

| Max output power @ 12V | 2.3W |

| No-load speed @ 6V | 40 rpm |

| Stall current @ 6V | 0.90A |

| Stall torque @ 6V | 5.5 kg·cm |

| Motor type | 12V, 1.8A stall (MP 12V) |

| Size | 25D x 54L mm |

| Weight | 91 g |

| Shaft diameter | 4 mm |

| Max efficiency @ 12V | 34% |

| Speed at max efficiency | 68 rpm |

| Torque at max efficiency | 1.6 kg·cm |

| Current at max efficiency | 0.28 A |

| Output power at max efficiency | 1.1 W |

The downloadable diagram shows the dimensions of the 25D line of metal gearmotors (units are mm over [inches]).

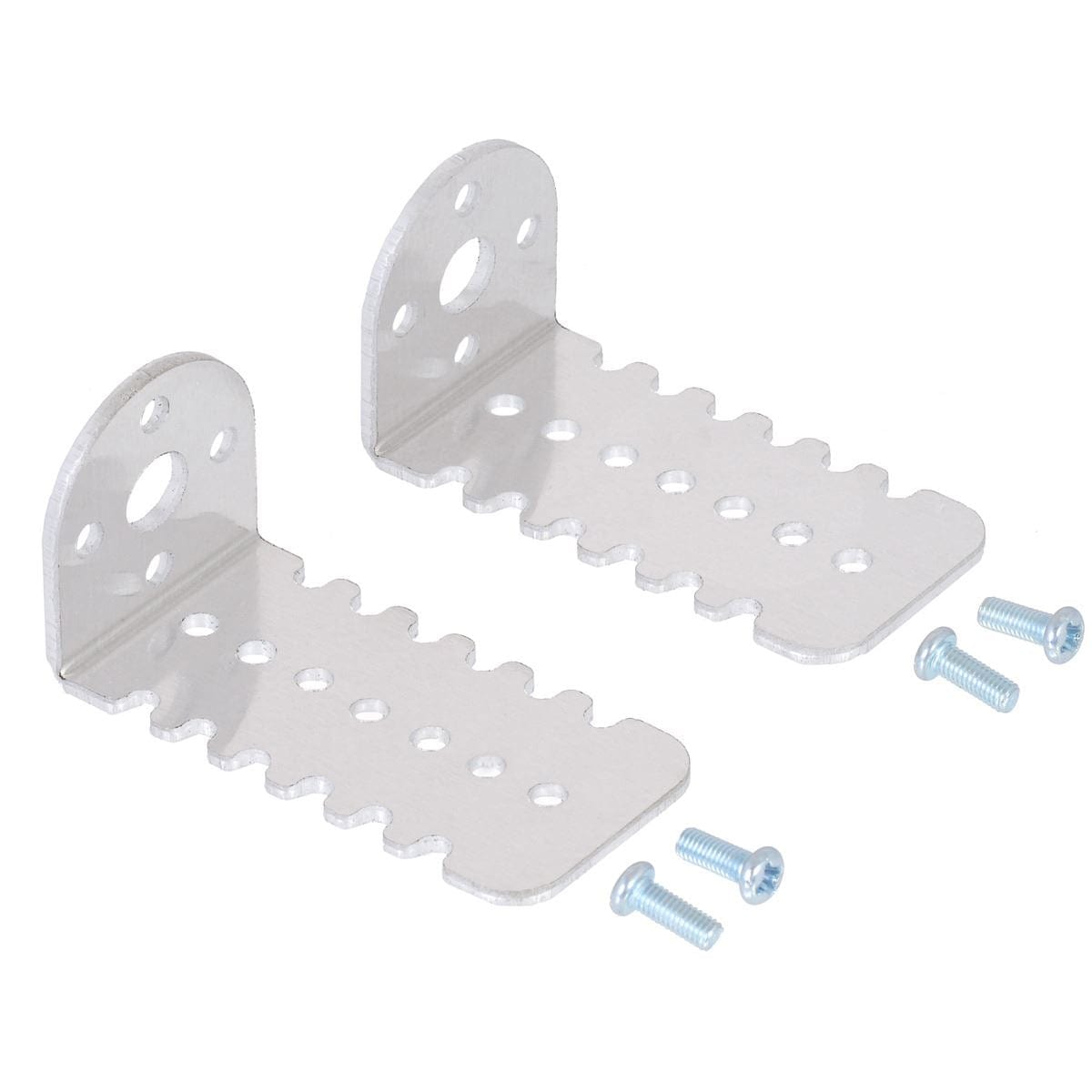

Warning: Do not screw too far into the mounting holes as the screws can hit the gears. We recommend screwing no more than 6mm into the screw holes.