Login / Signup

Cart

Your cart is empty

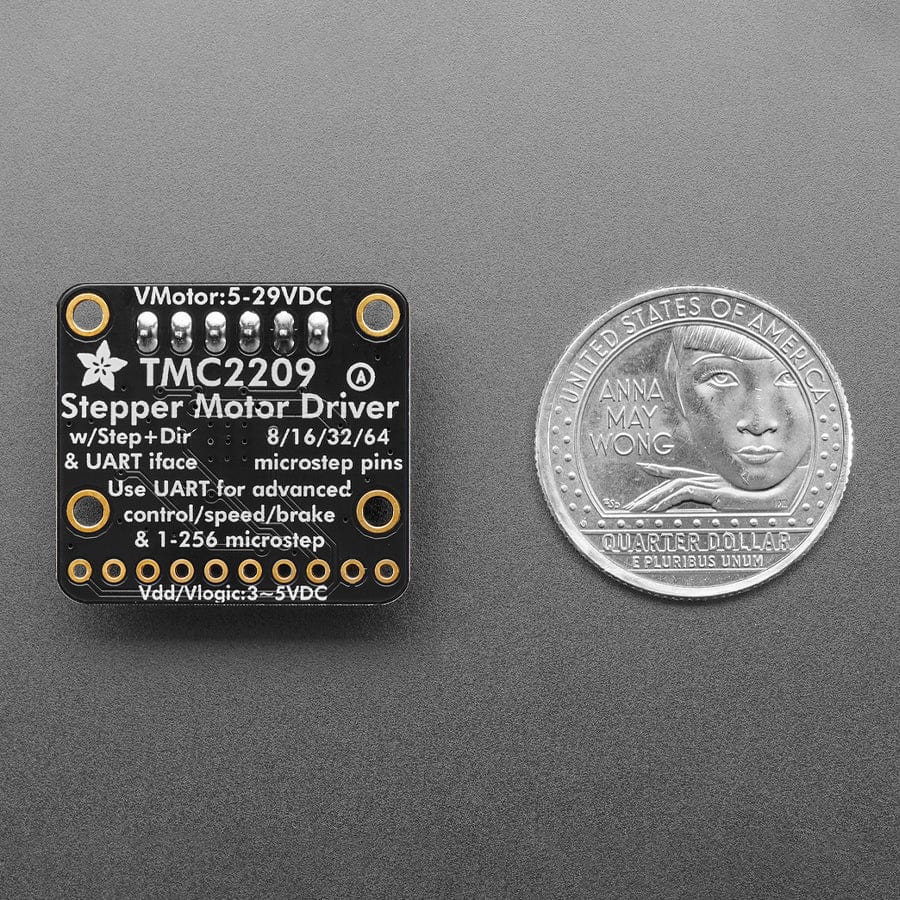

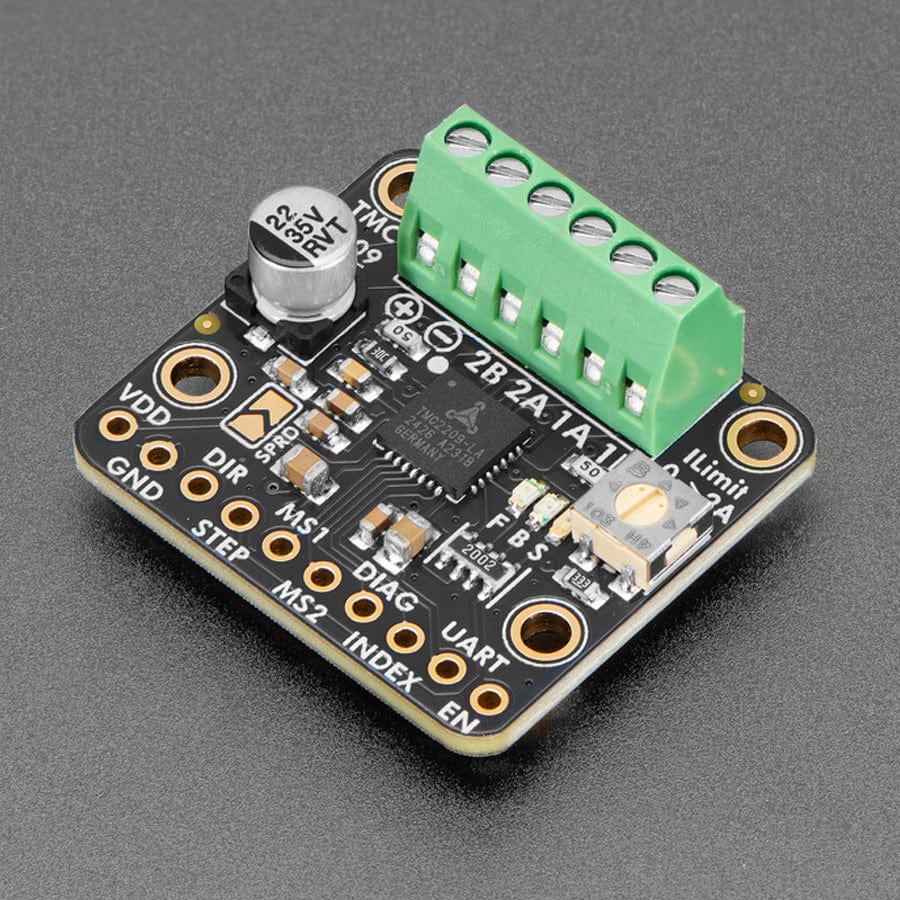

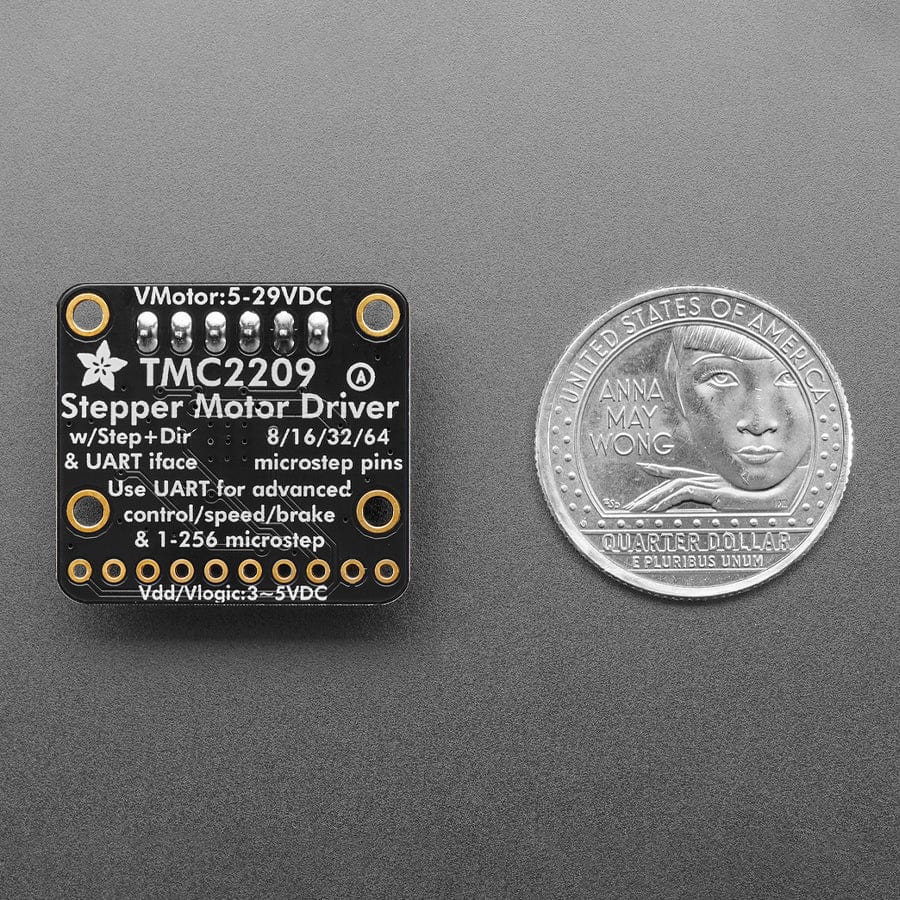

Stepper motors are used for CNC machines, 3D printers, and whenever else one needs precise, powerful motion. But to get good behavior from steppers you need a motor driver chip that can provide high bursts of current, and for smooth motion, be able to PWM that current for microstepping support. You can DIY this with a lot of timers, a microcontroller and an H-Bridge chip - or you could take the easy way out and use an Adafruit TMC2209 Stepper Motor Driver Breakout Board which makes controlling stepper motors easy-breezy and super-silent.

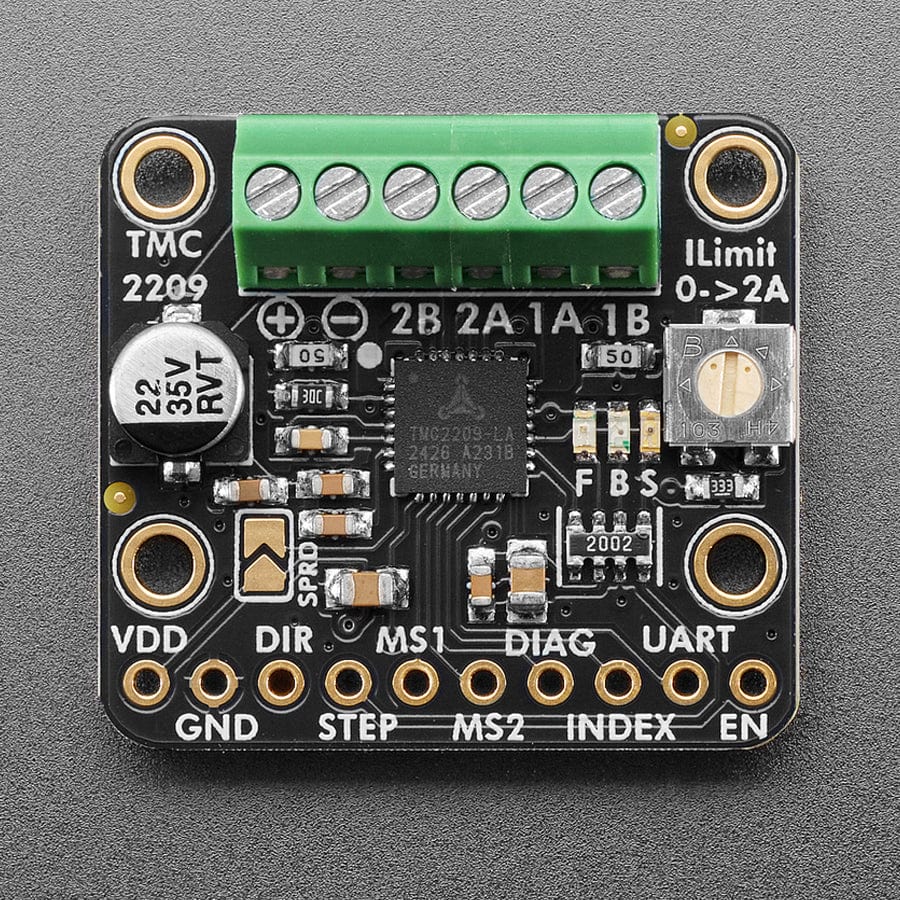

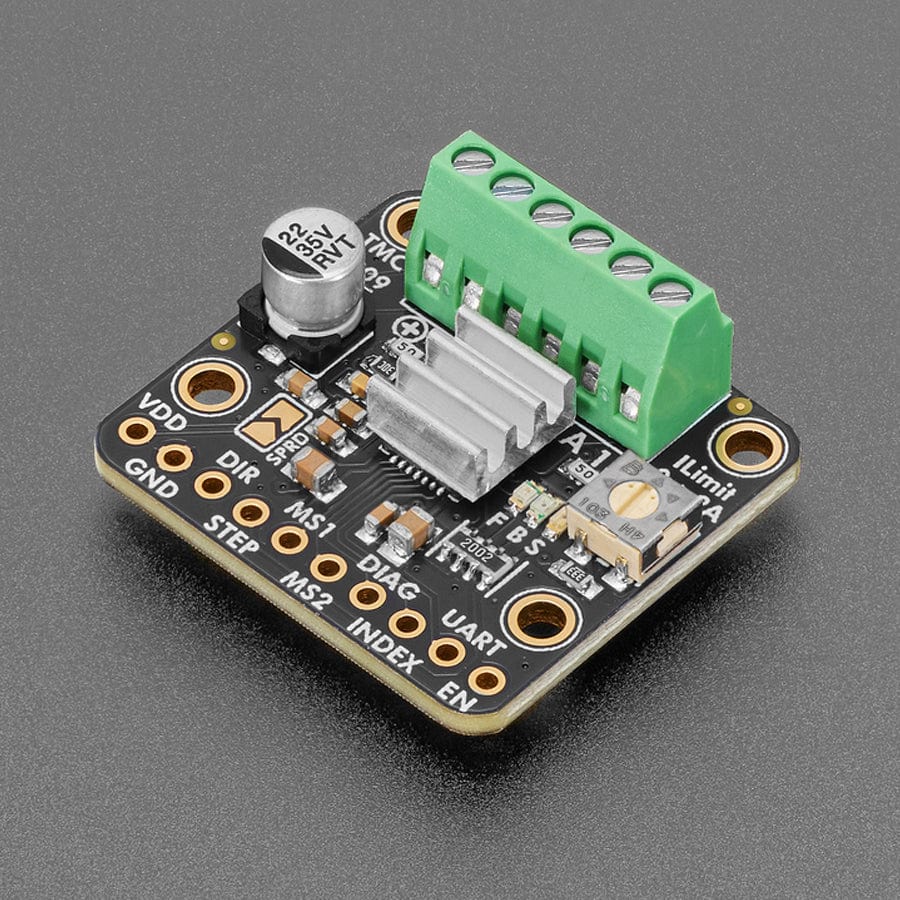

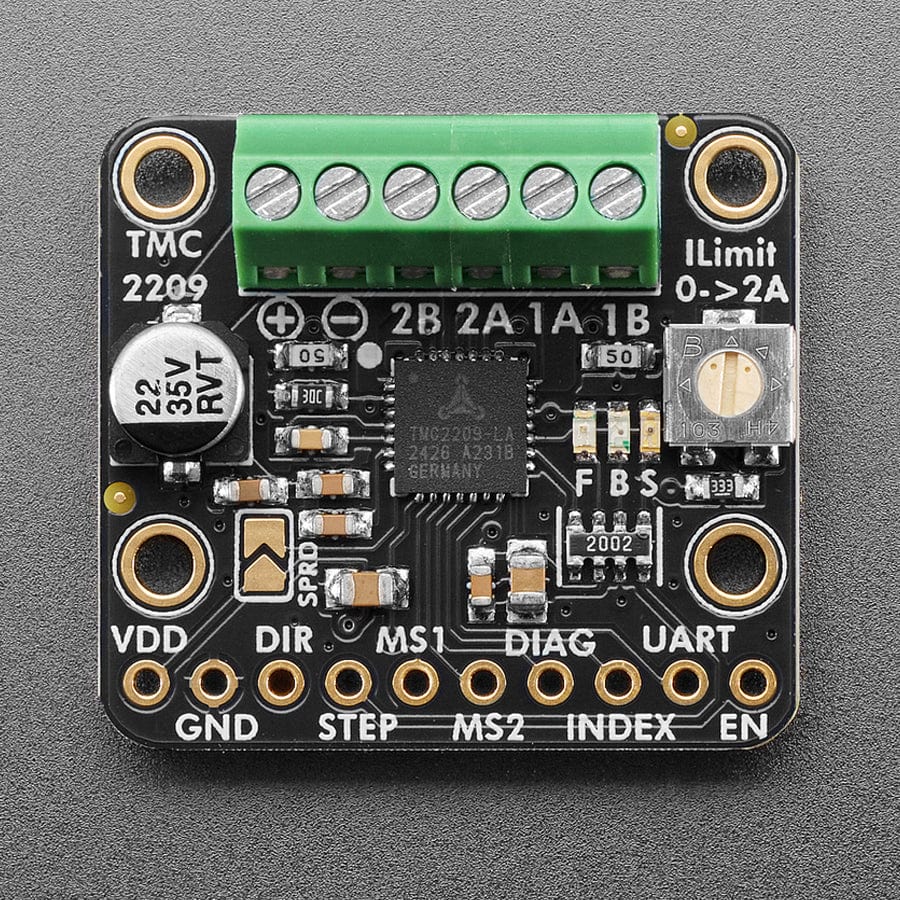

All you need is two output pins, no timers, PWM or real-time microcontroller. Set the DIRection pin high or low to set the spin orientation. Then toggle the STEP pin to take one microstep at a time. You can set whether you want to go faster with 1/8 microsteps or increase the precision to 1/16, 1/32 or 1/64 microsteps per STEP toggle. If you want more control, say to single-step or up to 1/256 microsteps, you can do so via the UART interface (more on that later). By default the driver is set to 1/8 microstep mode, you can change it by tying the MS1/MS2 pins high, either with jumpers or with 2 more output pins. The step/microstep mode can even be adjusted on the fly! LEDs on the DIR and STEP pins let you get visual feedback on your motor signal.

The Trinamic drivers are often known as "silent" or "stealth" chips - compared to the A4988 they are unbelievably quiet, you can barely tell they are running thanks to the micro-stepping techniques used. This reduces noise and wear, to make users happy. There are also a lot of niceties like index output which will pulse when the micro stepping counter cycles back to 'zero', and a diagnostic output to quickly alert the microcontroller of a big error like short or open circuits. It can also do 'sensor-less stop detection' with a feature called StallGuard - but for that, you will need to use the UART interface.

The UART interface is a single-pin serial port with auto-baud detection that allows more precise communication, diagnostics and control. You can do things like set microsteps from 1 to 256, or set the speed with a single command. You can also configure settings like current limiting, over-heat temperature limit, PWM frequency, etc. You'll need a microcontroller library to use UART and it's an 'extra' - not essential for basic motion control!

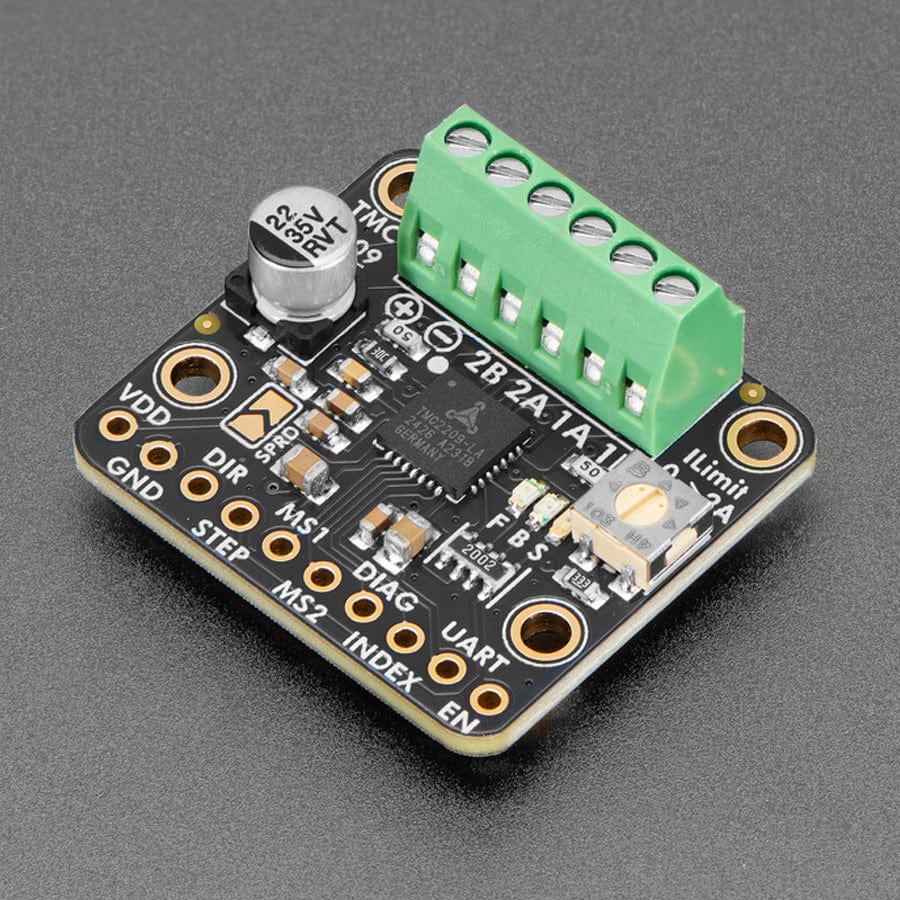

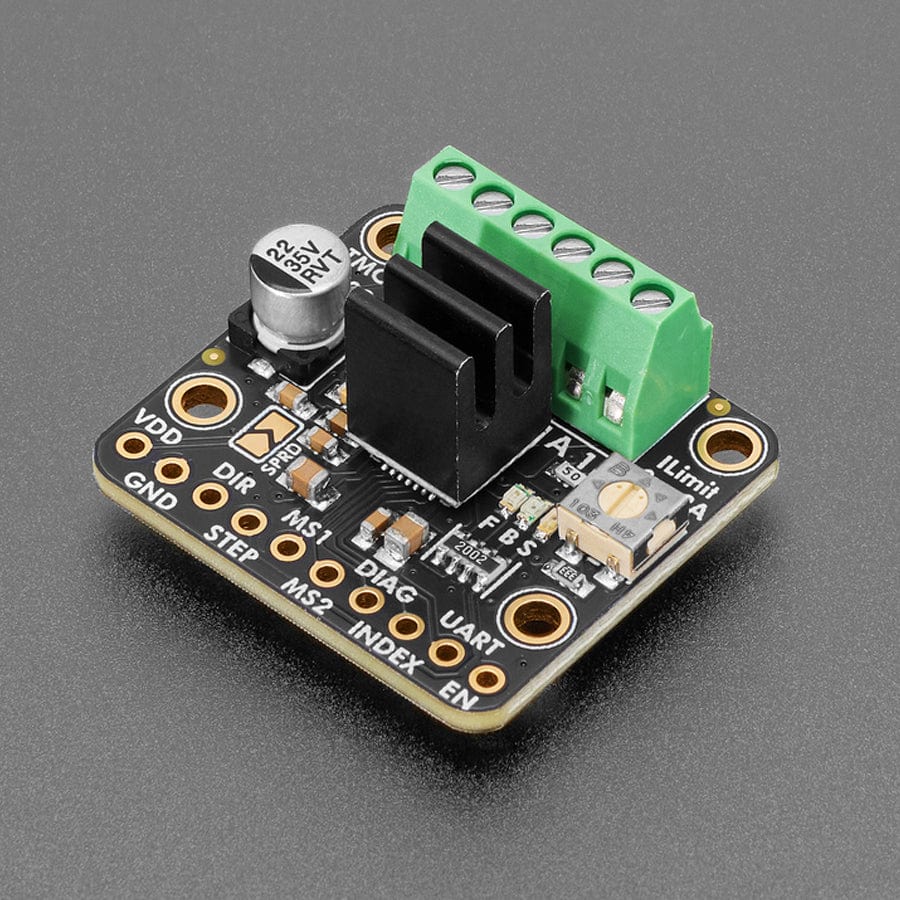

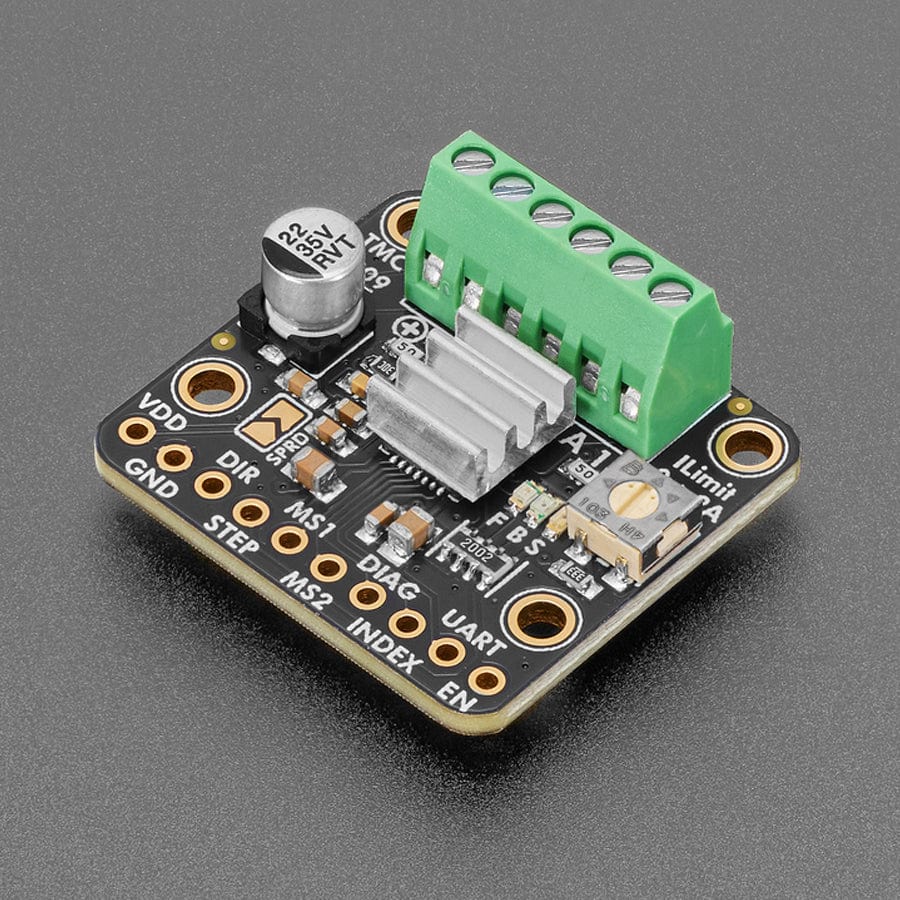

The Trinamic TMC2209 is a popular driver chip, with small breakout boards used in many 3D printers. Those breakouts are great for plugging into motherboards but are a little tough to use for prototyping. Our version comes with terminal blocks for the motor power and stepper wires, plus nicely labelled pins for control and mounting holes.

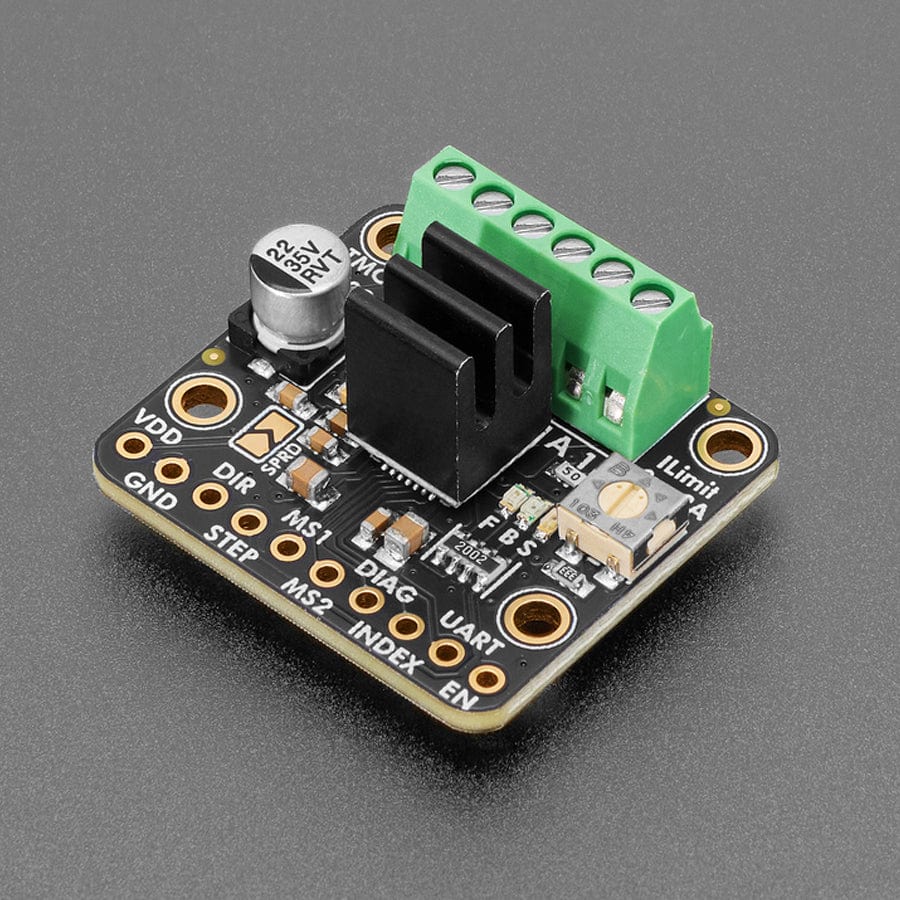

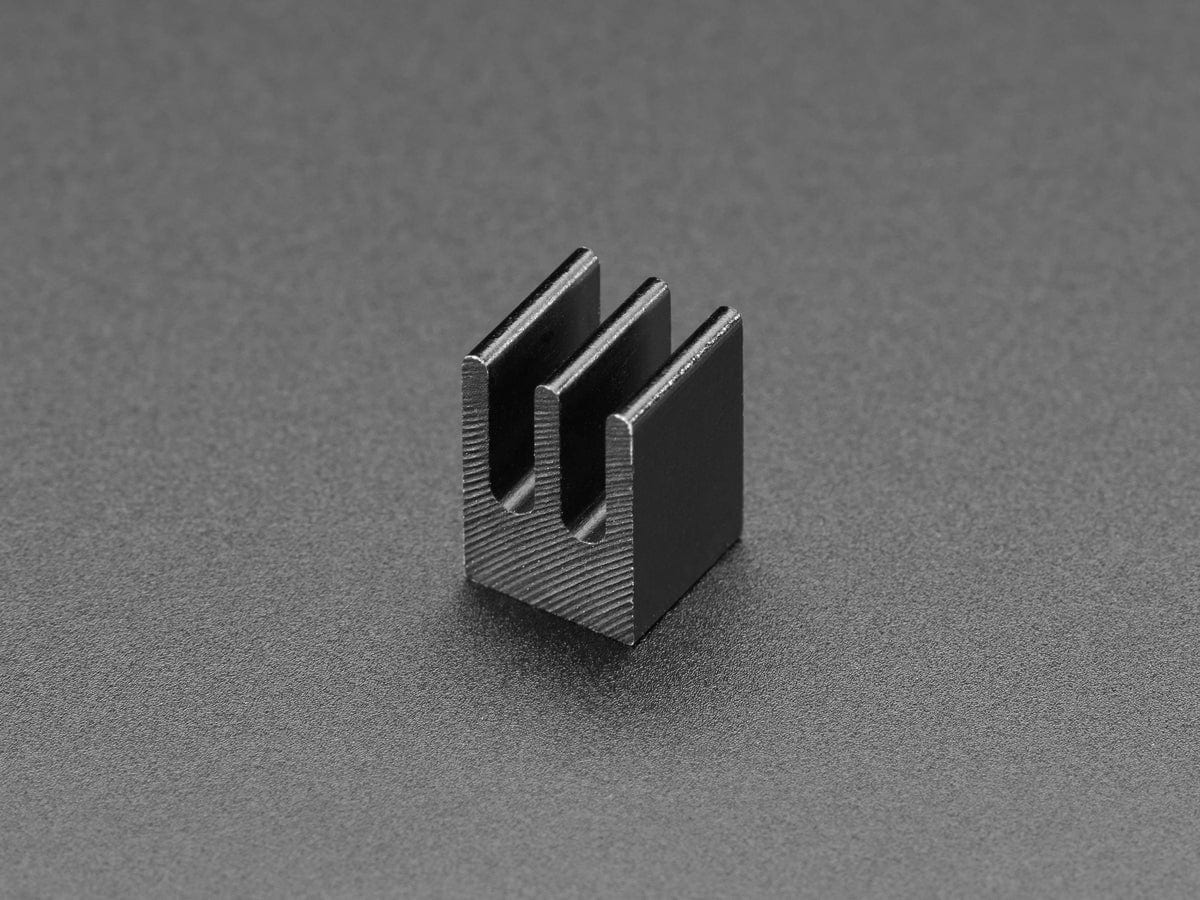

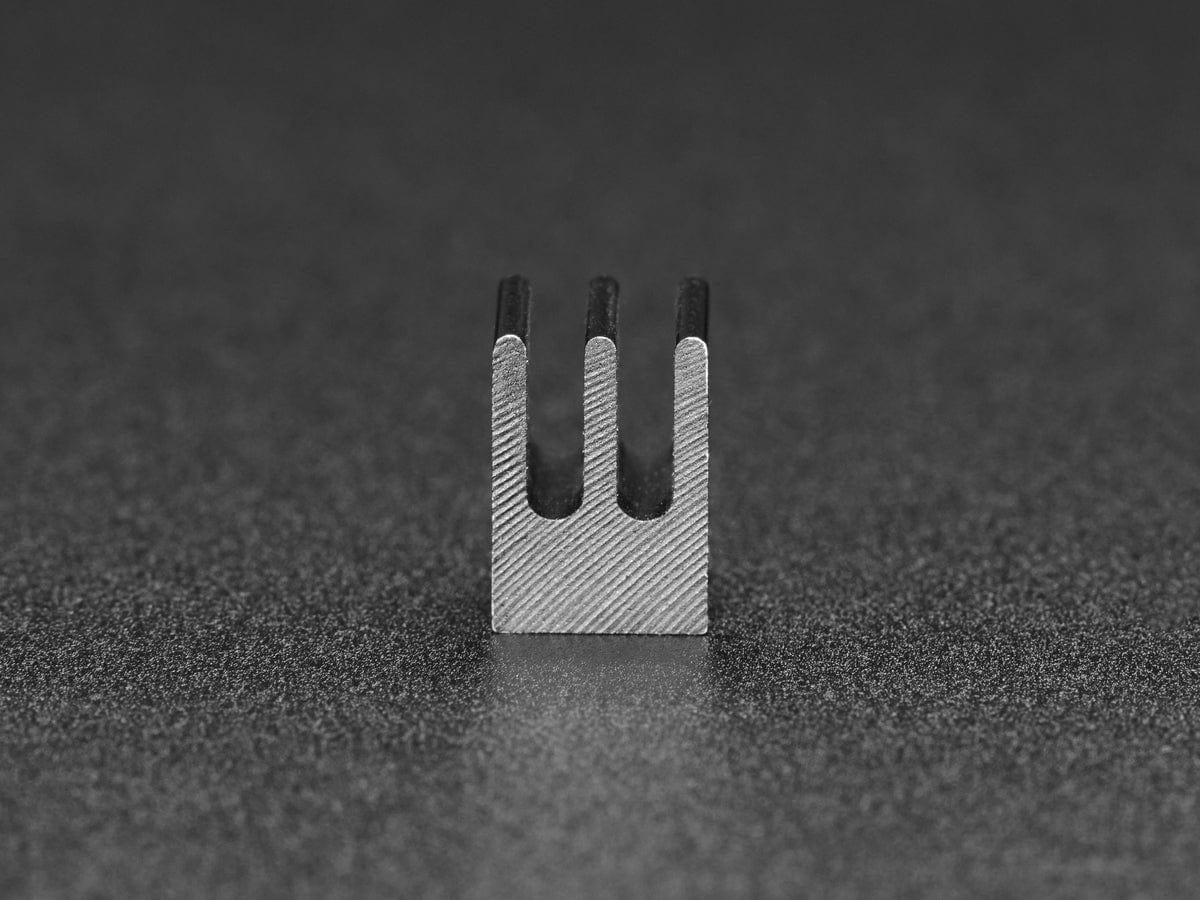

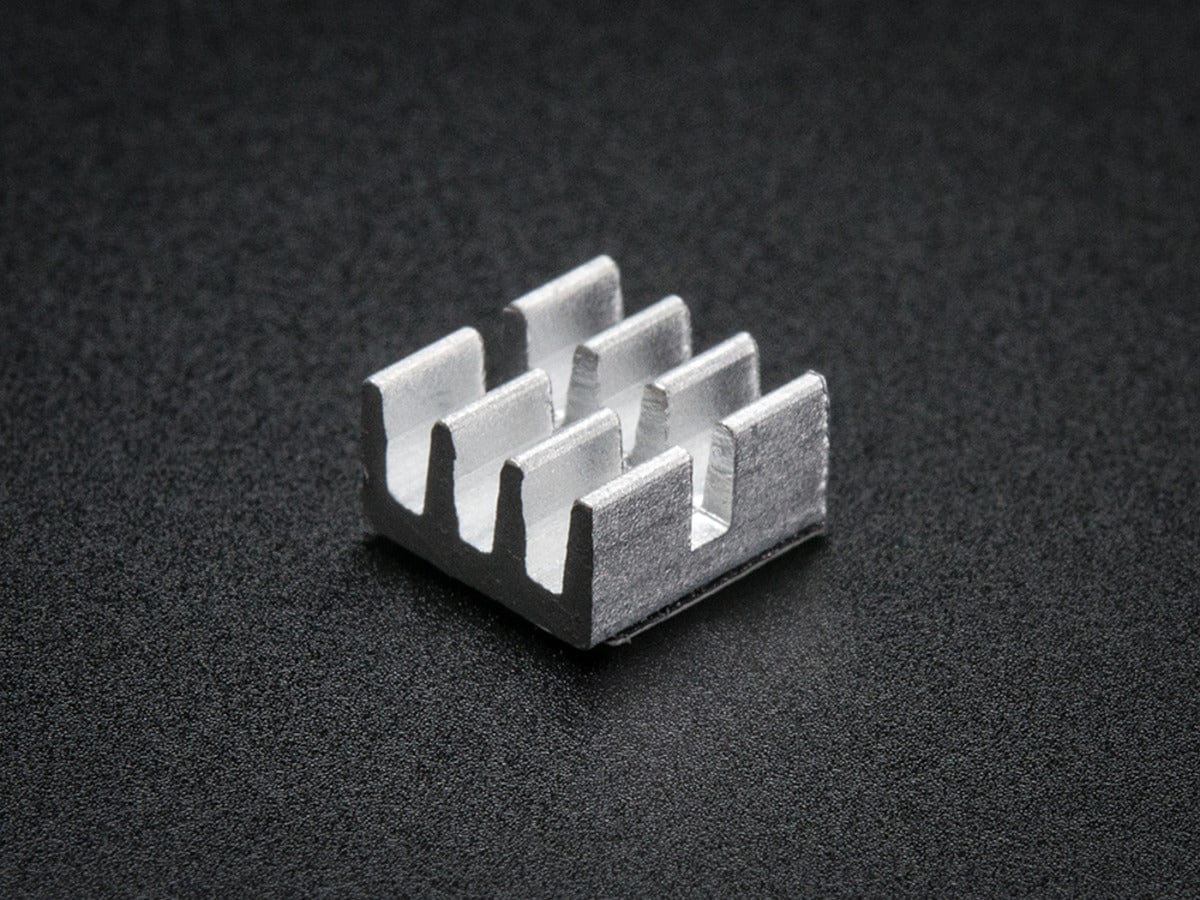

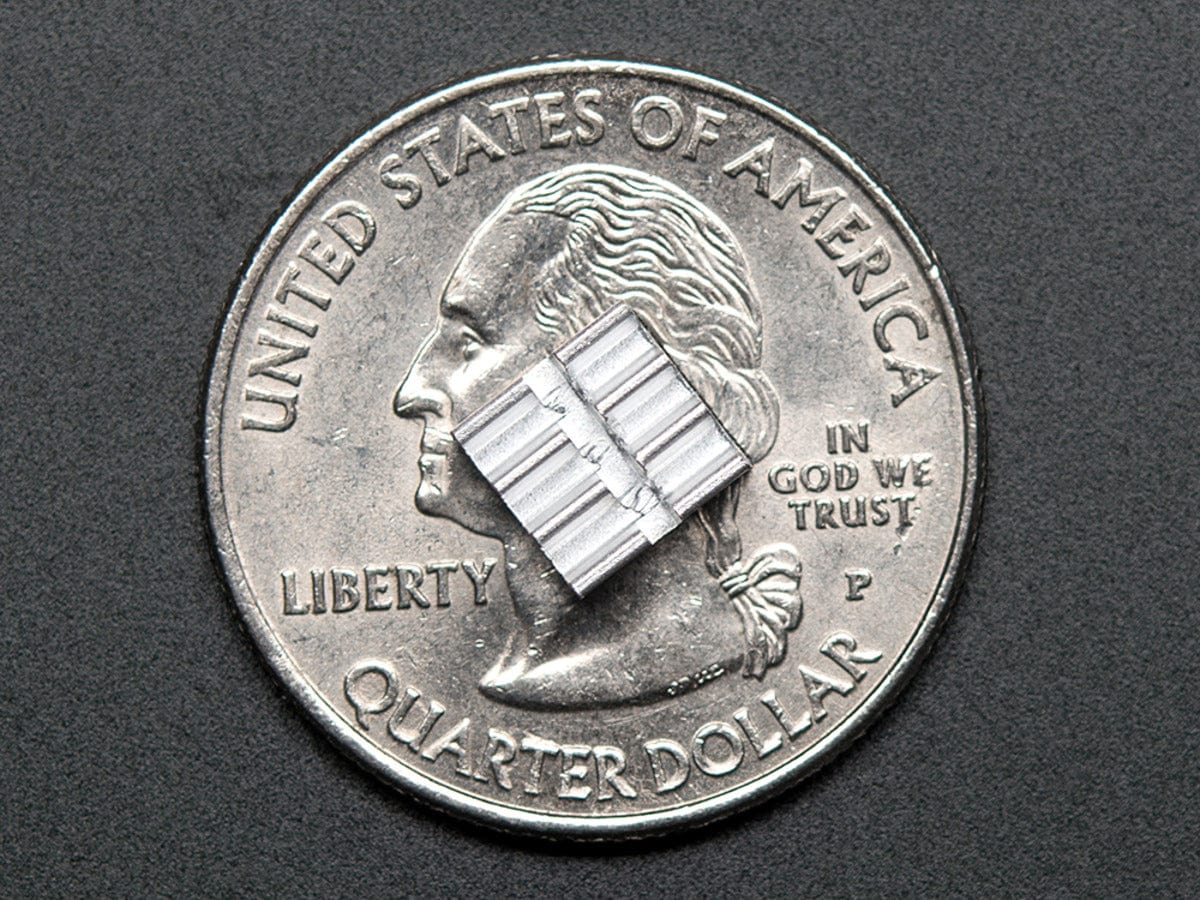

We fabricated the board with 2 oz copper to give it a hand with the 2A-max current that this driver can handle. To use the current limiting capability, twist the onboard potentiometer: when to the right we can get to up to 2A max. Note that the higher the currents will heat up both the motor driver and stepper so you may need to add heatsinking to the chip. We DON'T include a heatsink but you can get a tall ~80ºC/W or short ~90ºC/W heatsink to attach on top.

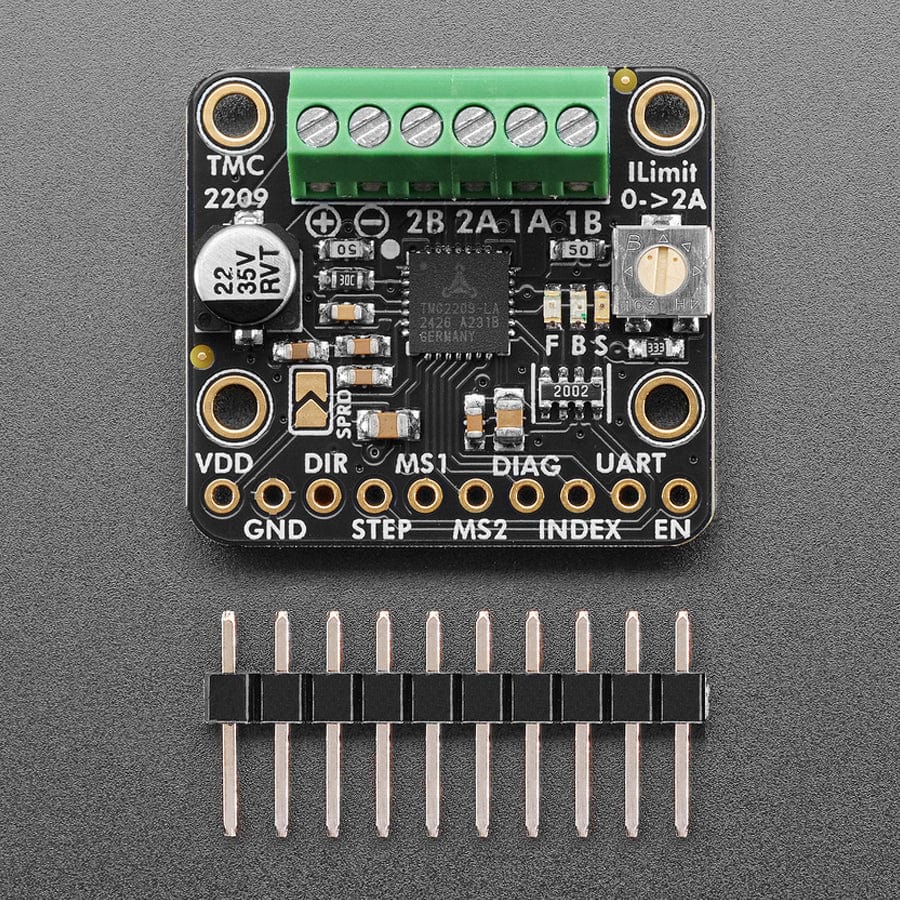

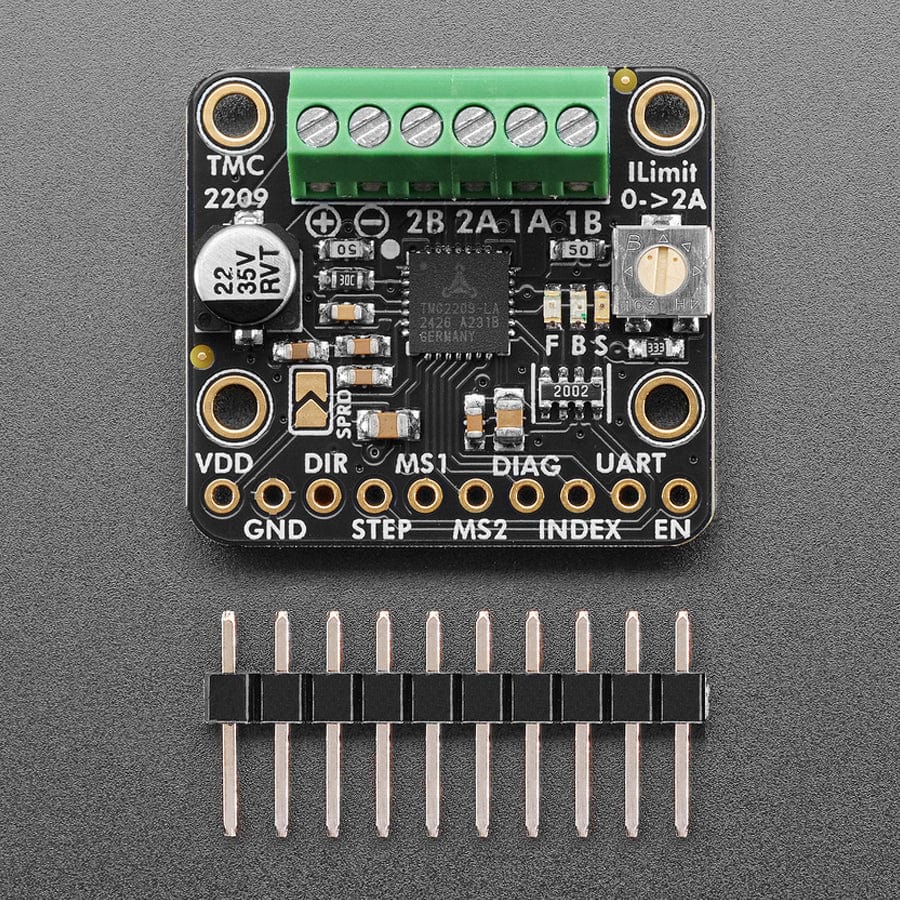

Note: Comes as one assembled and tested breakout plus a small strip of header. You'll need to do some light soldering to attach the header onto the breakout PCB. You will need some sort of driver board that will toggle the DIR/STEP pins for you.