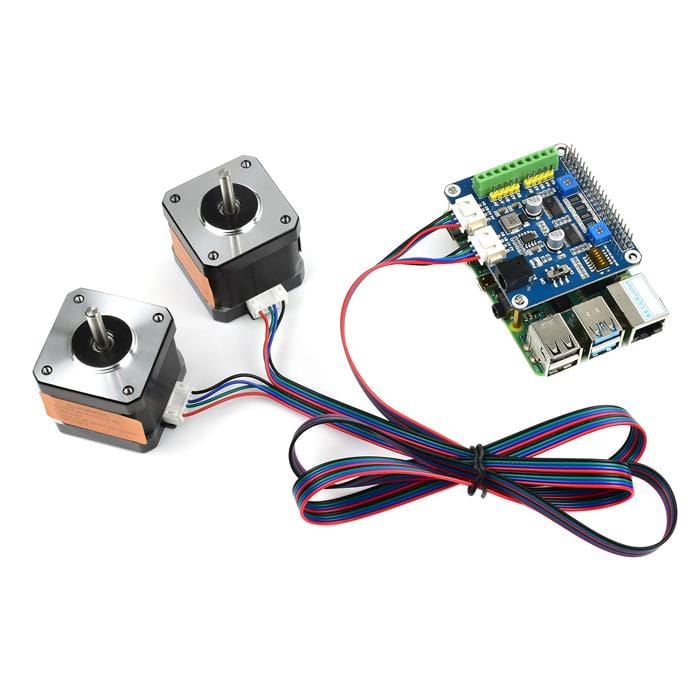

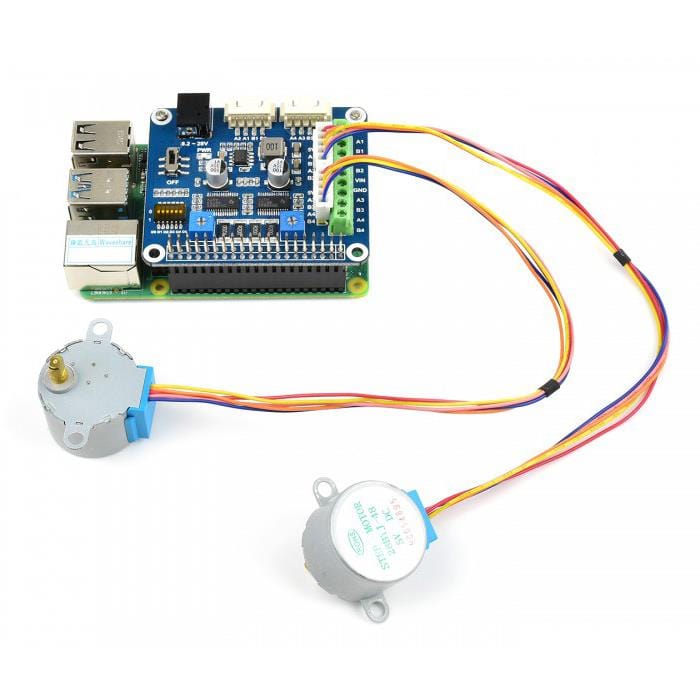

Stepper Motor HAT for Raspberry Pi

Price:

Sale price

£27

Stock:

Quantity:

Cart

Your cart is empty

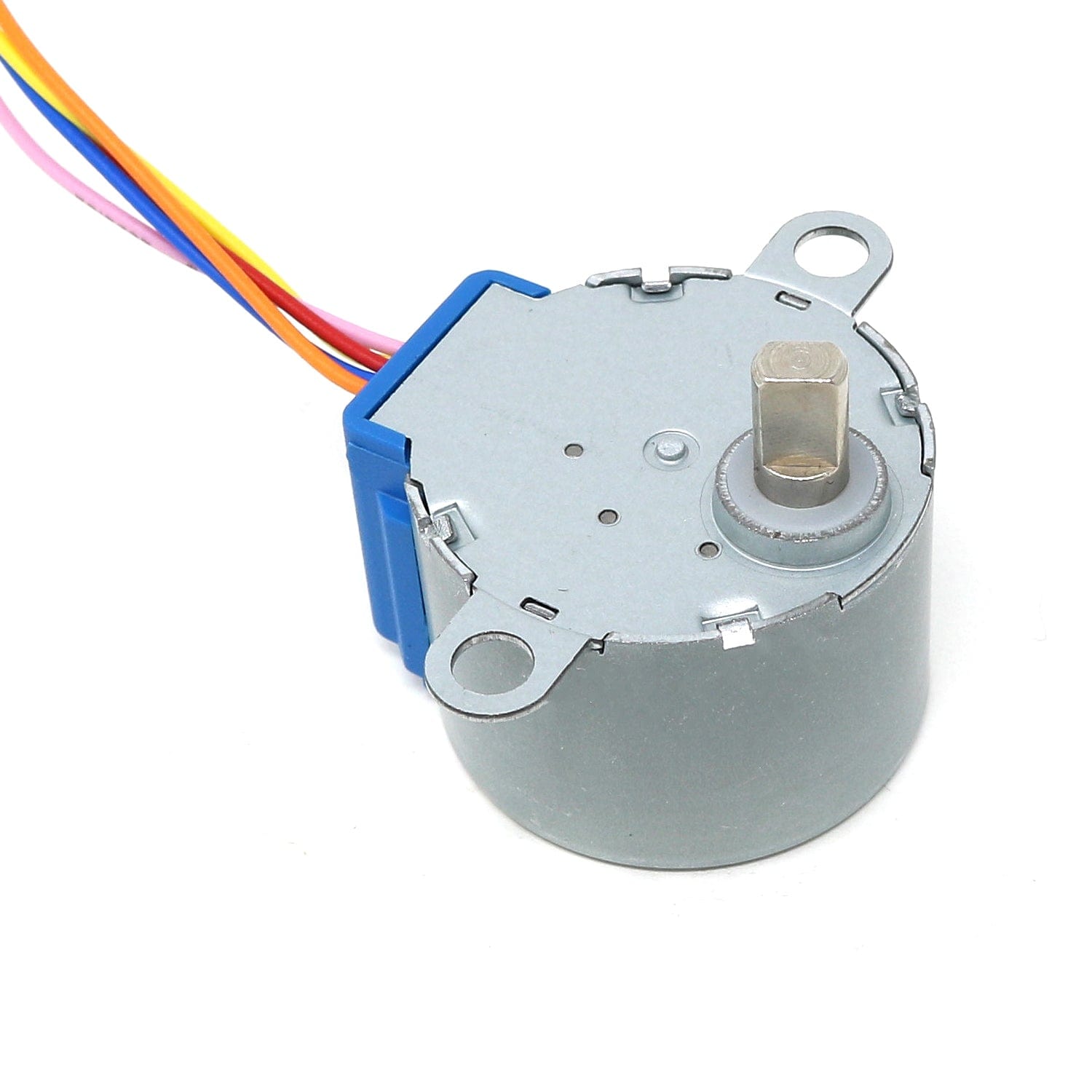

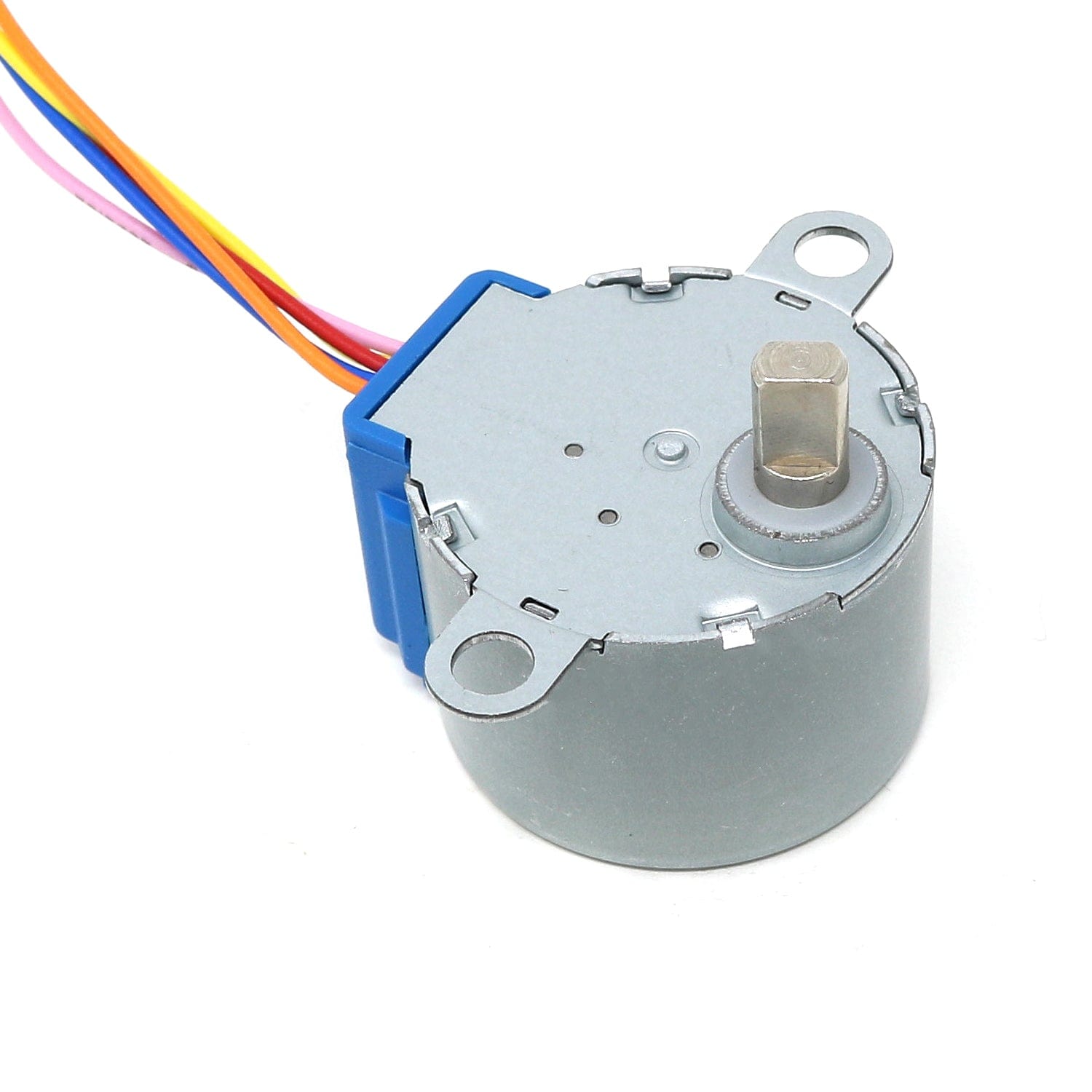

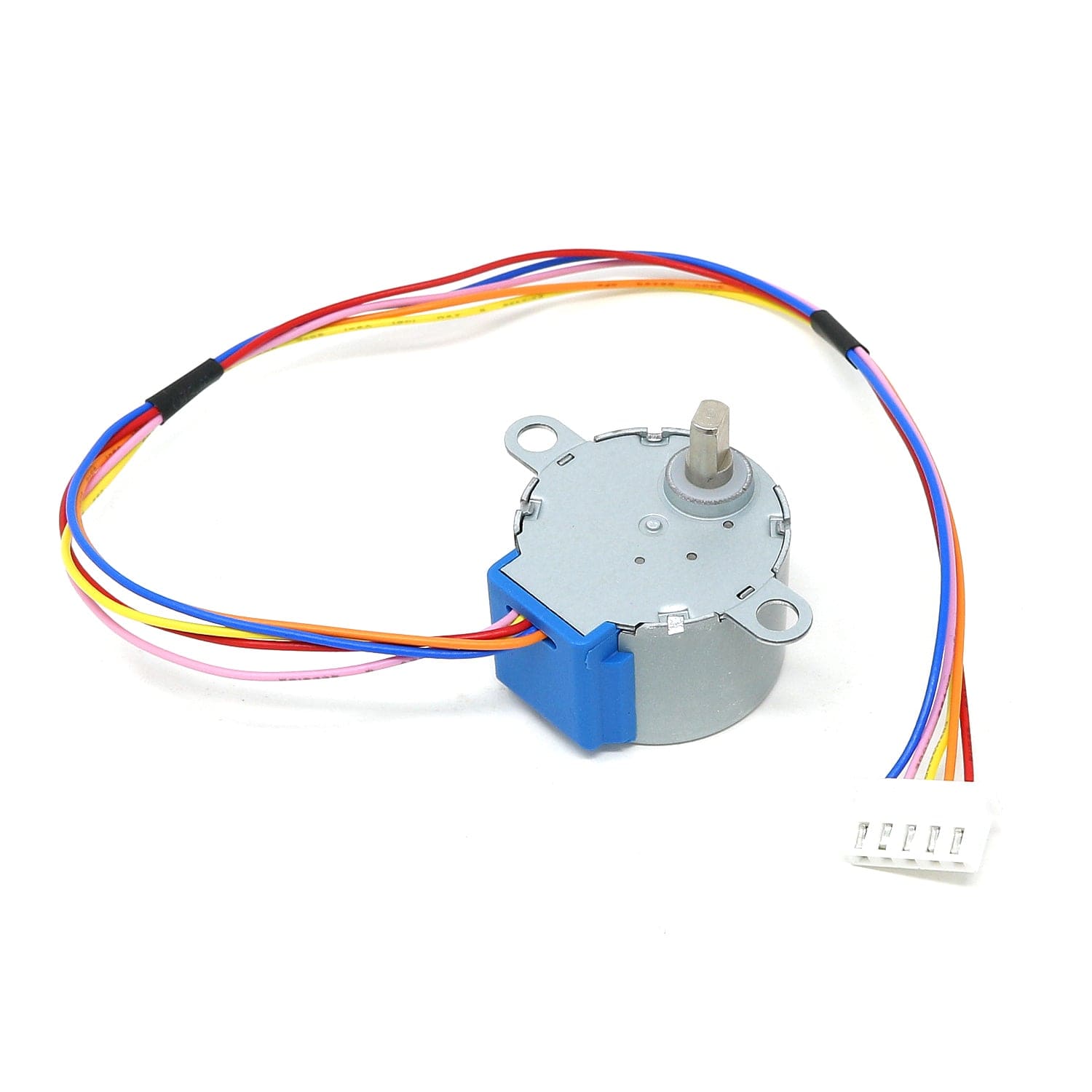

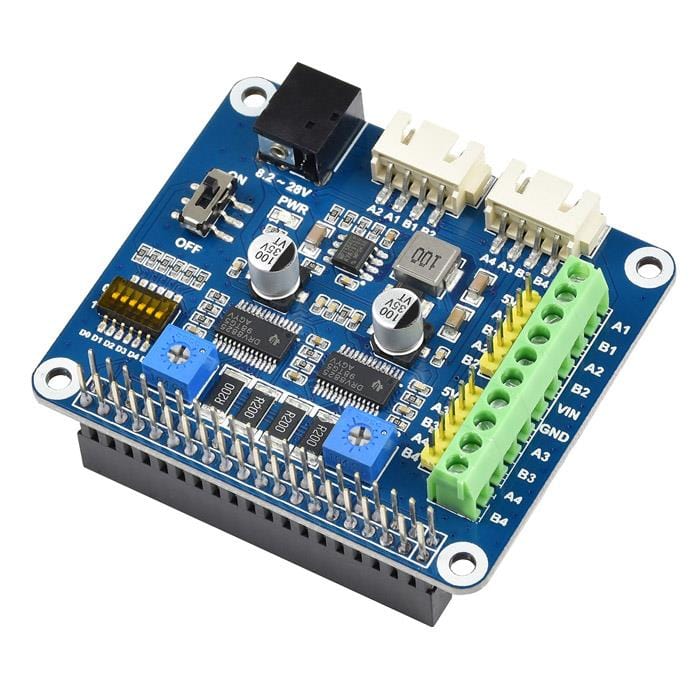

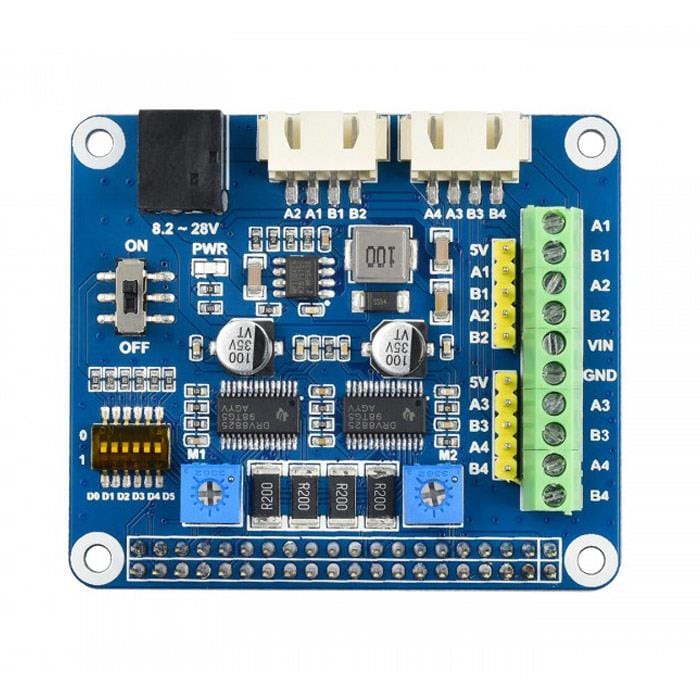

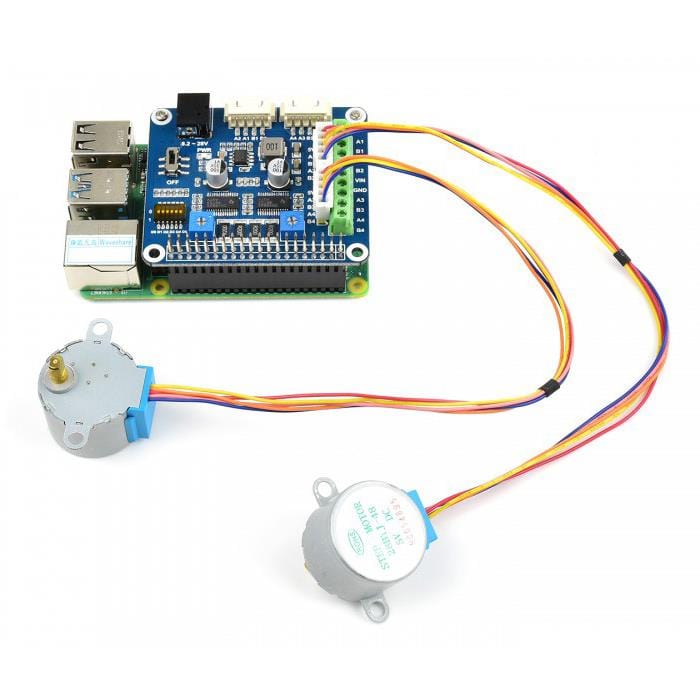

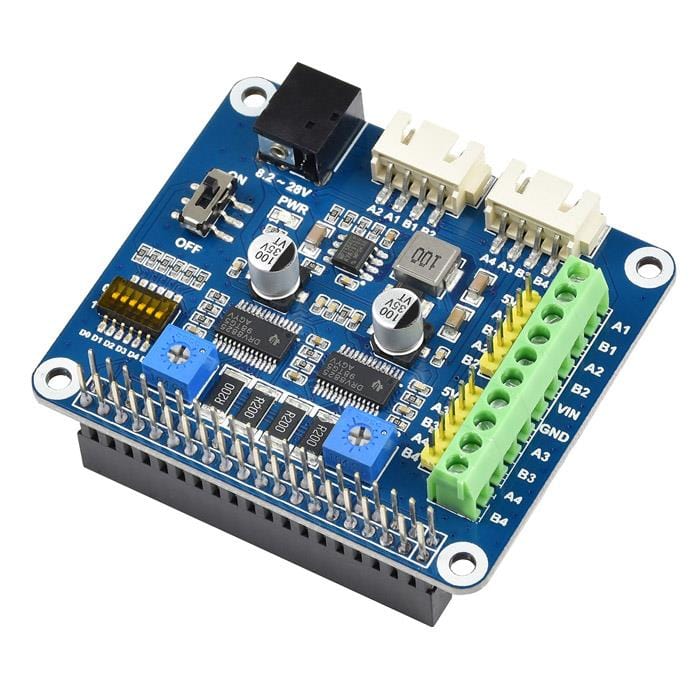

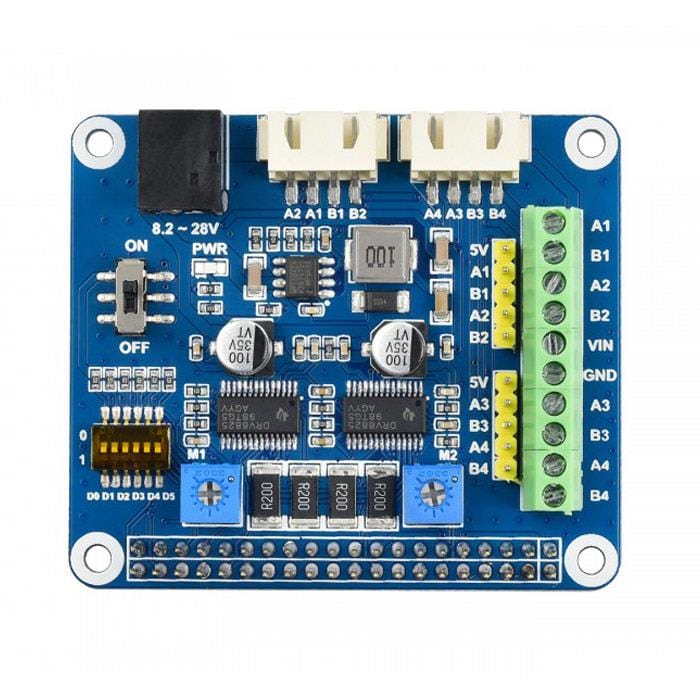

This Stepper Motor HAT gives your Raspberry Pi the ability to drive two stepper motors at the same time and supports up to 1/32 microstepping. This version uses a DRV8825 controller.

The HAT features six step modes (full-step, half-step, 1/4-step, 1/8-step, 1/16-step, and 1/32-step) and includes multiple connector options to accommodate a range of stepper motors.

An onboard 5V regulator has been included to power your Raspberry Pi.

Note: Stepper motors NOT included

New content loaded

Login / Signup