Login / Signup

Cart

Your cart is empty

This black 30T Pololu Tract Set contains components for adding a tracked drive system to a small robot or vehicle.

This track set includes a pair of silicone tracks, two black drive sprockets measuring 35mm (1.4″) in diameter, and two matching idler sprockets along with mounting hardware.

To work properly with the track, the drive and idler sprockets should be set up approximately 85 mm (3.35″) apart. The drive sprockets are designed to work with 3mm D-shafts, such as those on micro metal gearmotors. These are the same tracks and sprockets used on the Zumo chassis.

Also available in red and white, or as a 22T set!

Note: Track set only. Chassis, motors and other robot parts are not included.

The flexible one-piece silicone tracks are designed to mesh with the drive and idler sprockets.

The drive sprockets are designed to press-fit securely on the output shafts of our micro metal gear motors. On the Zumo robots, these gear motors are intended to be mounted with the raised lip on one side of the drive sprocket facing away from the motor, but if you are not using a Zumo chassis, you can insert the drive sprockets onto the 3mm D-shafts in either orientation.

Although the drive sprockets are similar to the hubs used in our 42×19mm wheels, they are not as wide, so they do not physically support the whole tire.

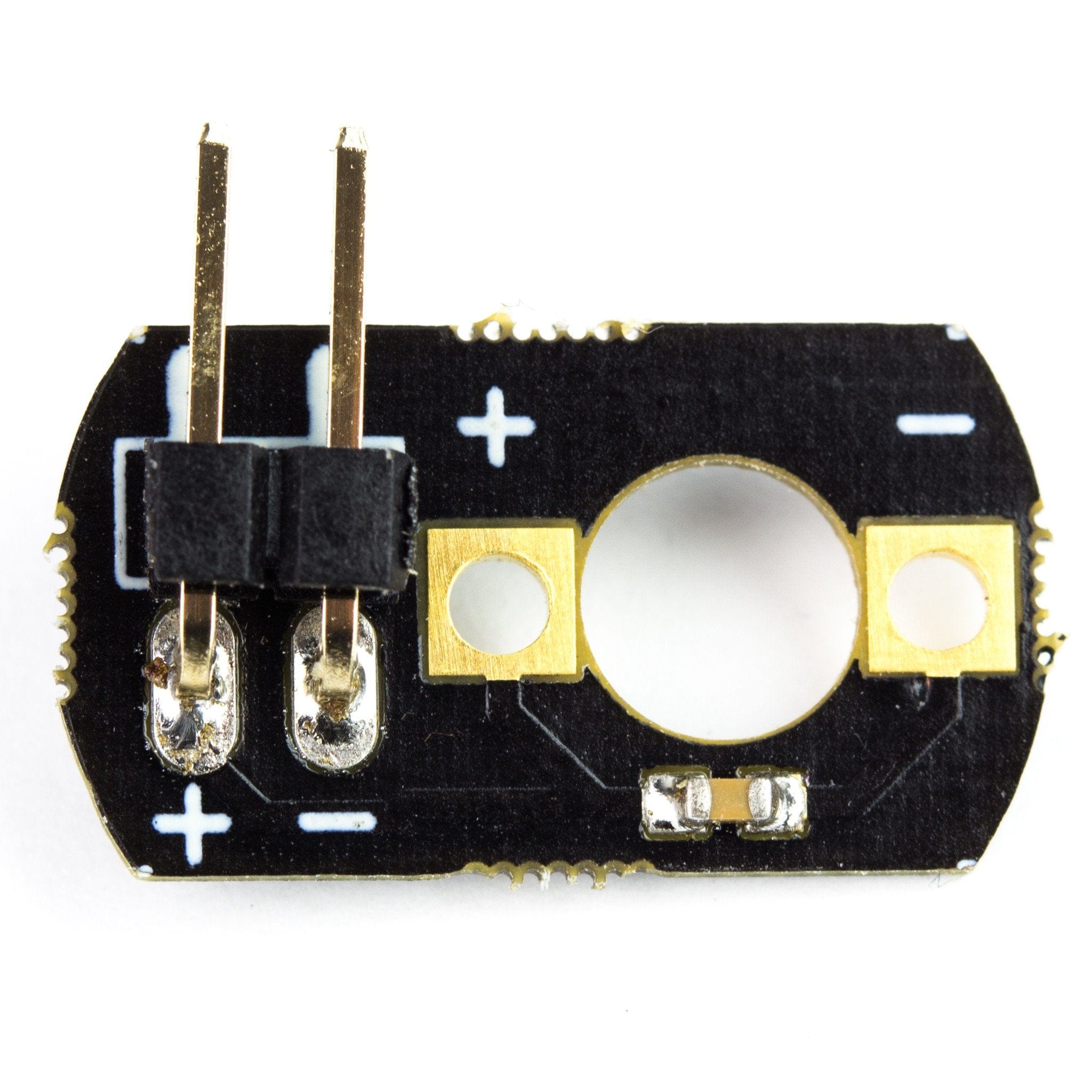

A pair of idler sprockets are also included in the set; these are very similar to the drive sprockets, with the main difference being that they are designed to spin freely instead of attaching to a motor shaft. They can be mounted with the provided shoulder bolts as shown in the diagram below. (The blue component labelled “ROBOT CHASSIS” represents a bracket or piece of a robot chassis that the sprocket is being mounted to, and is not a part included in the set.)

Included are two pairs of shoulder bolts, one with a 5mm threaded portion and one a 12mm threaded portion, so you can pick the pair that is appropriate for your application. You will only use two of the four included shoulder bolts.

A dimension diagram containing the sprockets, tracks, and bolts is available here. Several key dimensions are highlighted below:

The threaded portion of the shoulder bolts can be cut to the desired length.

The ideal spacing between the centres of the two sprockets is about 85 mm. Because the tracks are elastic, they will maintain tension even if you do not precisely match this distance. However, if the spacing is too short, they will be loose and more likely to slip off; if the spacing is too long, additional strain will be placed on the sprocket shafts, and the motor might not be able to turn as well.

These track sets are similar to the original 22T and 30T track sets, except they replace the old sprockets with newer, spoked versions. This spoked design removes material from several areas near the central hub of the sprocket, which has the advantage of allowing the drive sprocket to be more easily removed from the D-shaft of the motor while still remaining firmly fixed after being press-fit into place.