Login / Signup

Cart

Your cart is empty

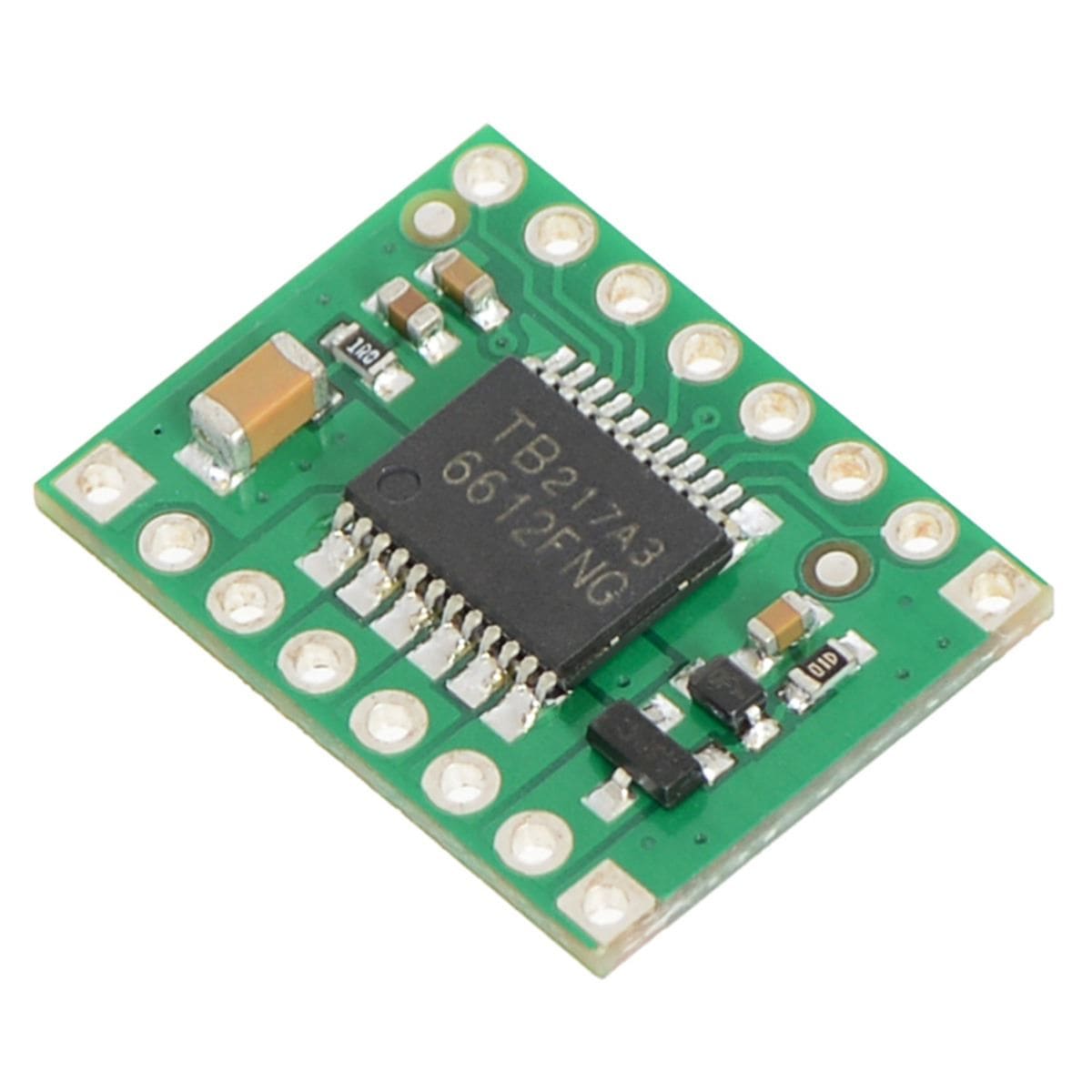

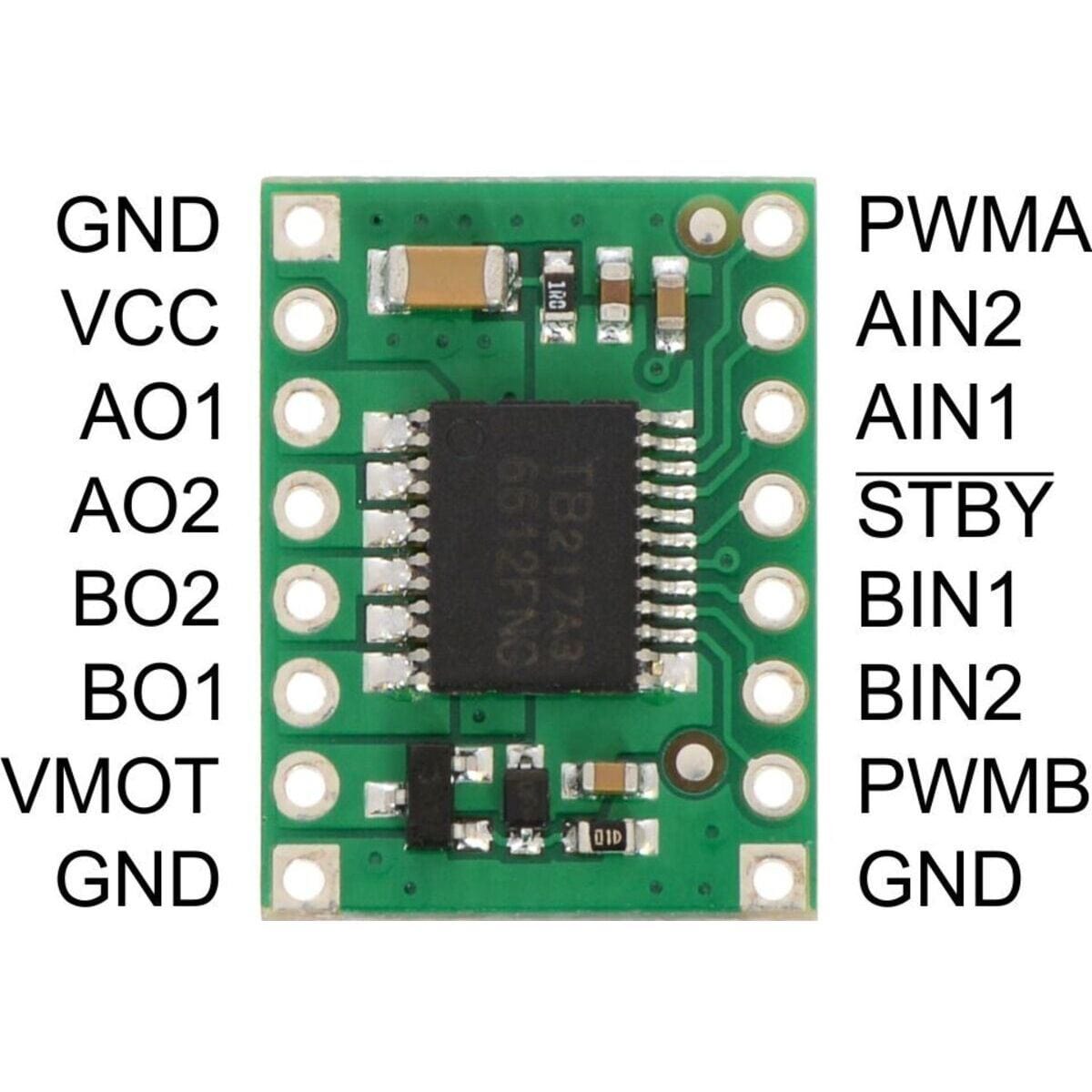

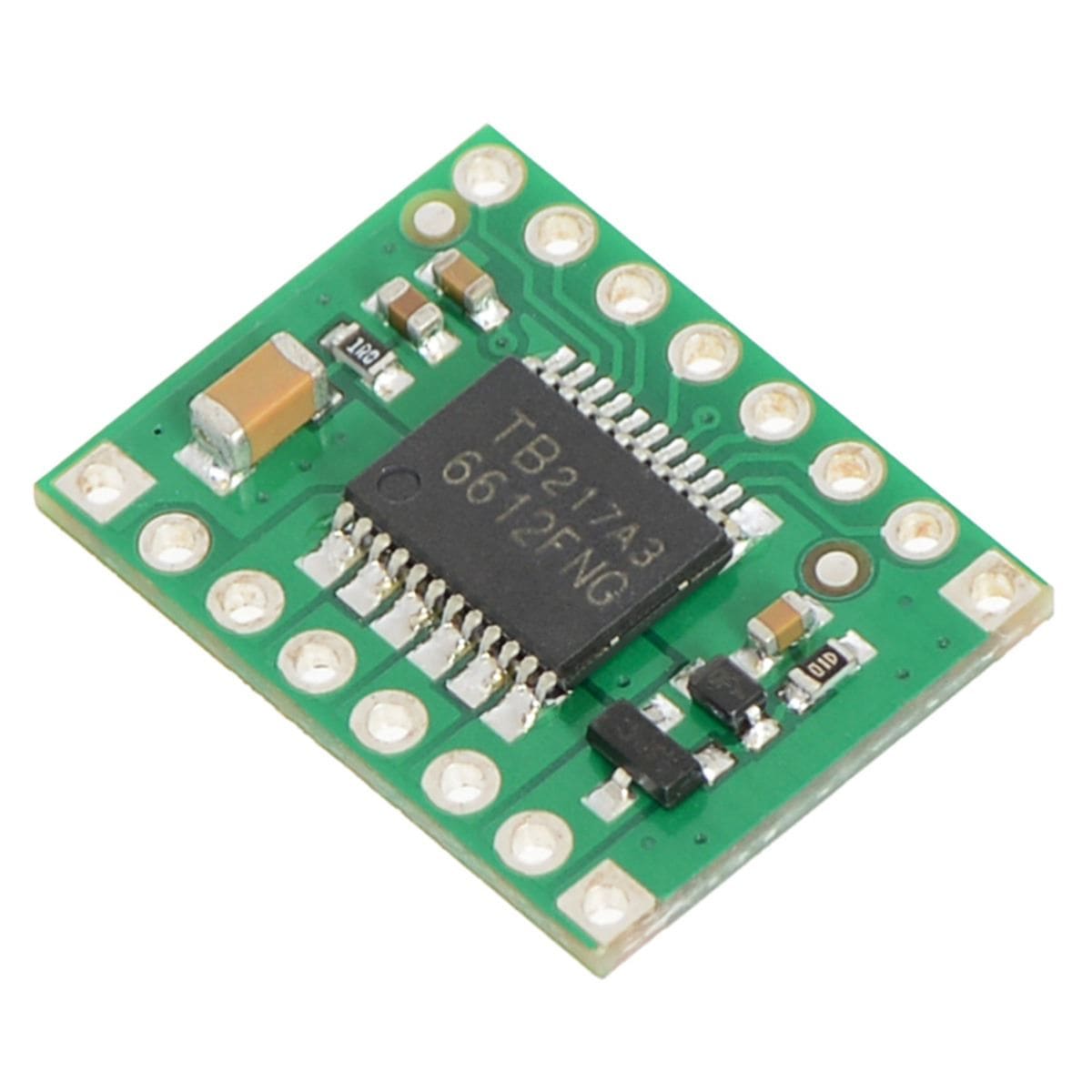

This tiny Pololu board is an easy way to use Toshiba’s TB6612FNG dual motor driver, which can independently control two bidirectional DC motors or one bipolar stepper motor. A recommended motor voltage of 4.5 V to 13.5 V and peak current output of 3 A per channel (1 A continuous) make this a great motor driver for low-power motors.

Warning: This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

The TB6612FNG is a great dual motor driver that is perfect for interfacing two small DC motors such as our micro metal gearmotors to a microcontroller, and it can also be used to control a single bipolar stepper motor.

The MOSFET-based H-bridges are much more efficient than the BJT-based H-bridges used in older drivers such as the L298N and Sanyo’s LB1836M, which allows more current to be delivered to the motors and less to be drawn from the logic supply (the LB1836 still has the TB6612 beat for really low-voltage applications). Our little breakout board gives you direct access to all of the features of the TB6612FNG and adds power supply capacitors and reverse battery protection on the motor supply (note: there is no reverse protection on the Vcc connection).

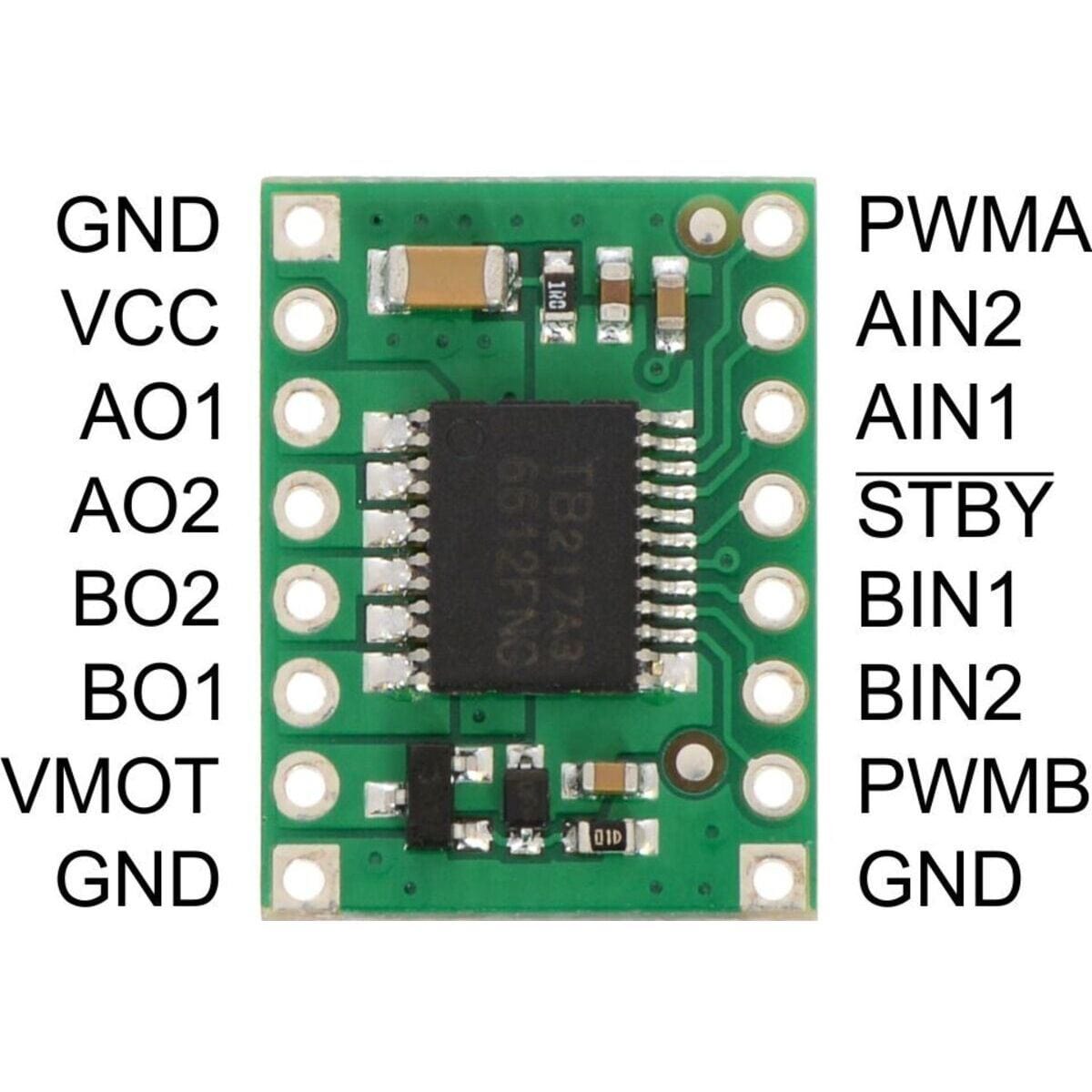

In a typical application, power connections are made on one side of the board and control connections are made on the other. All of the control inputs are internally pulled low. Each of the two motor channels has two direction control pins and a speed control pin that accepts a PWM input with a frequency of up to 100 kHz. The STBY pin must be driven high to take the driver out of standby mode.

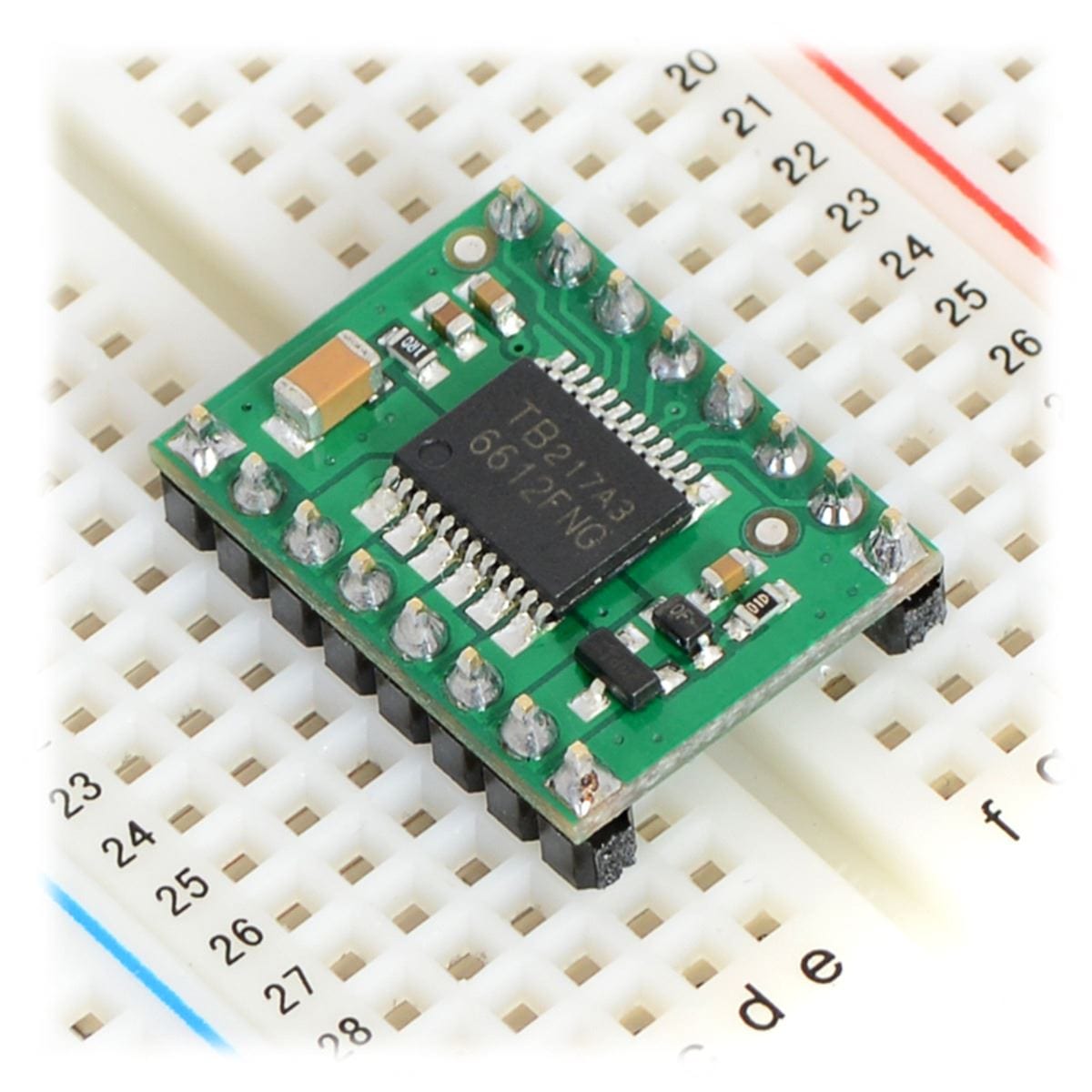

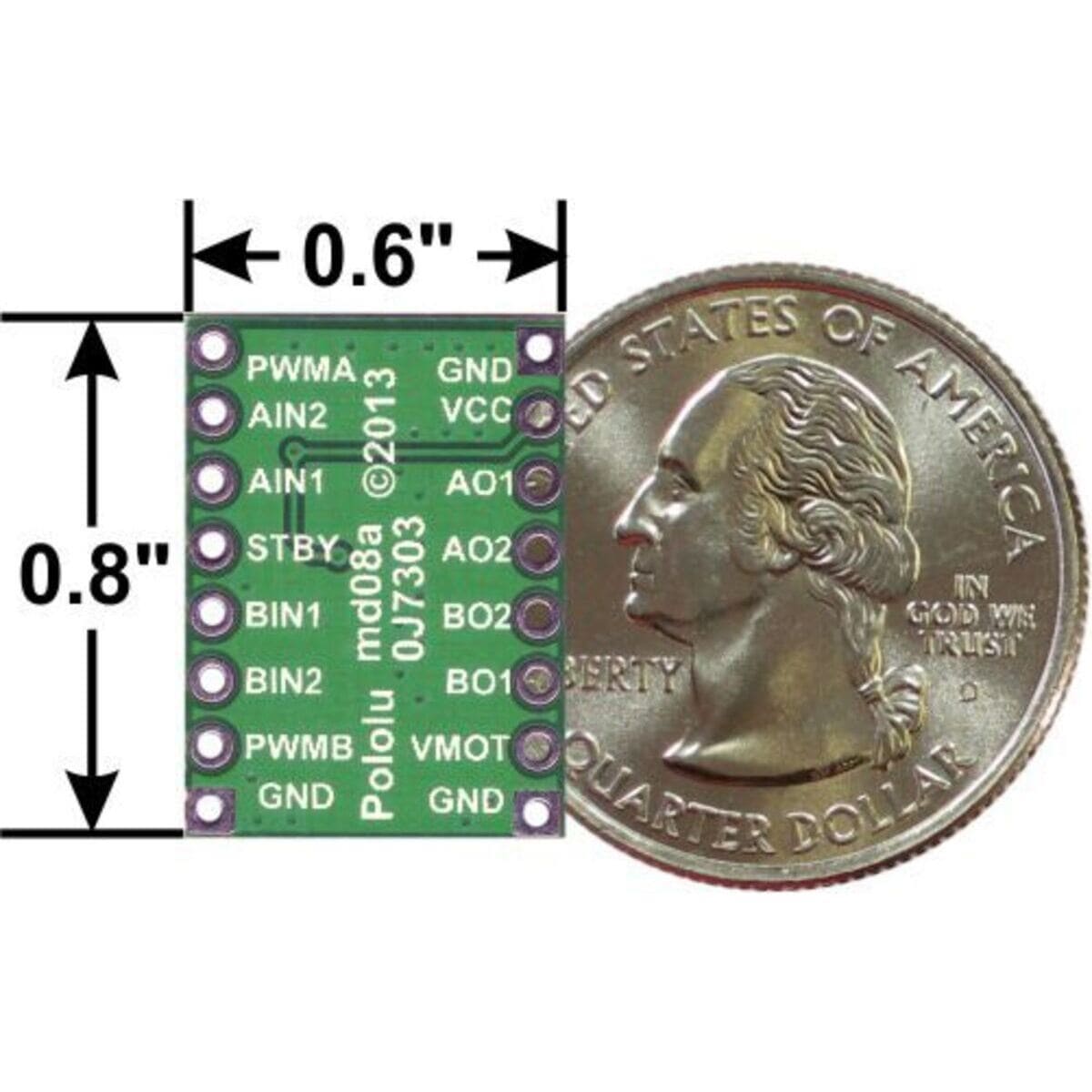

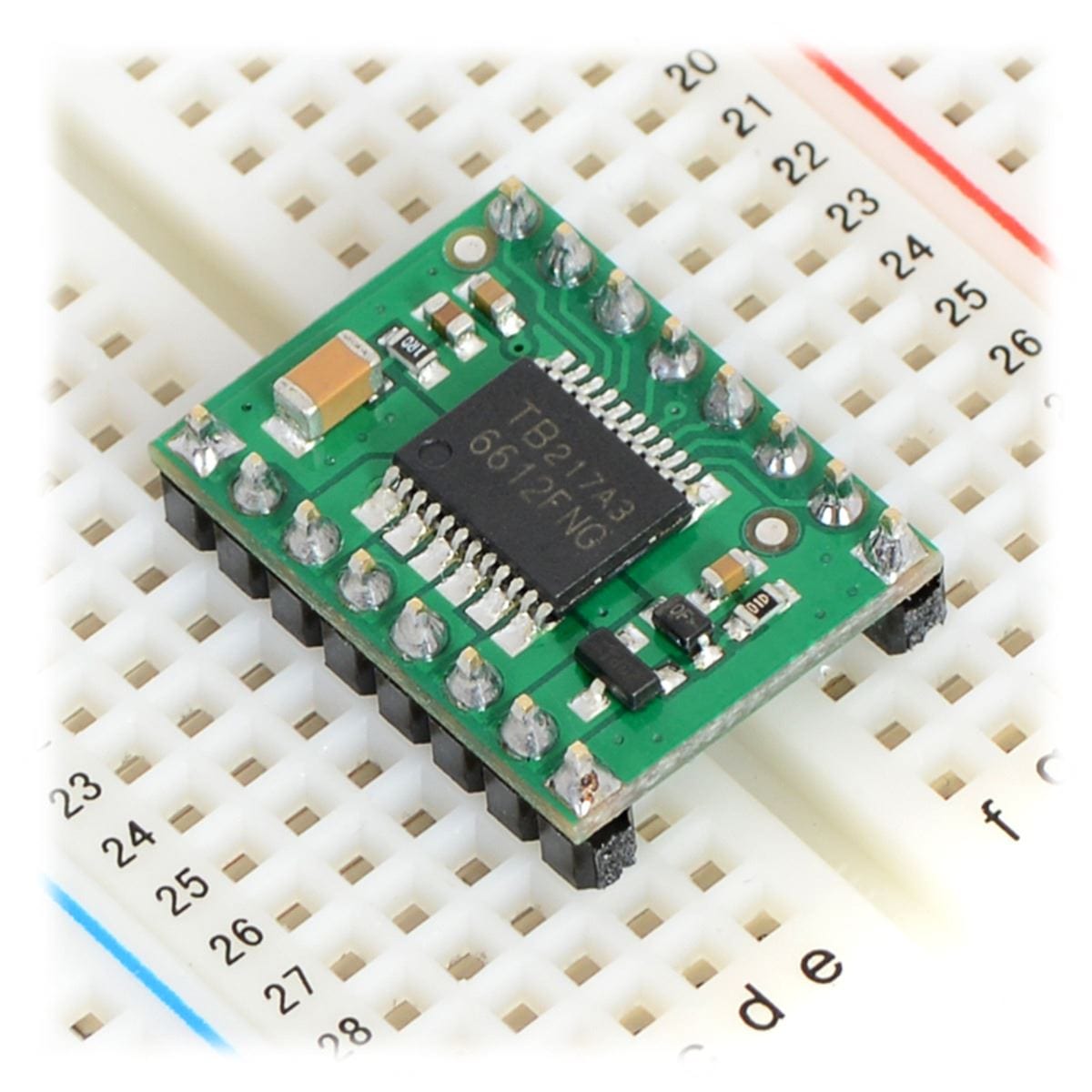

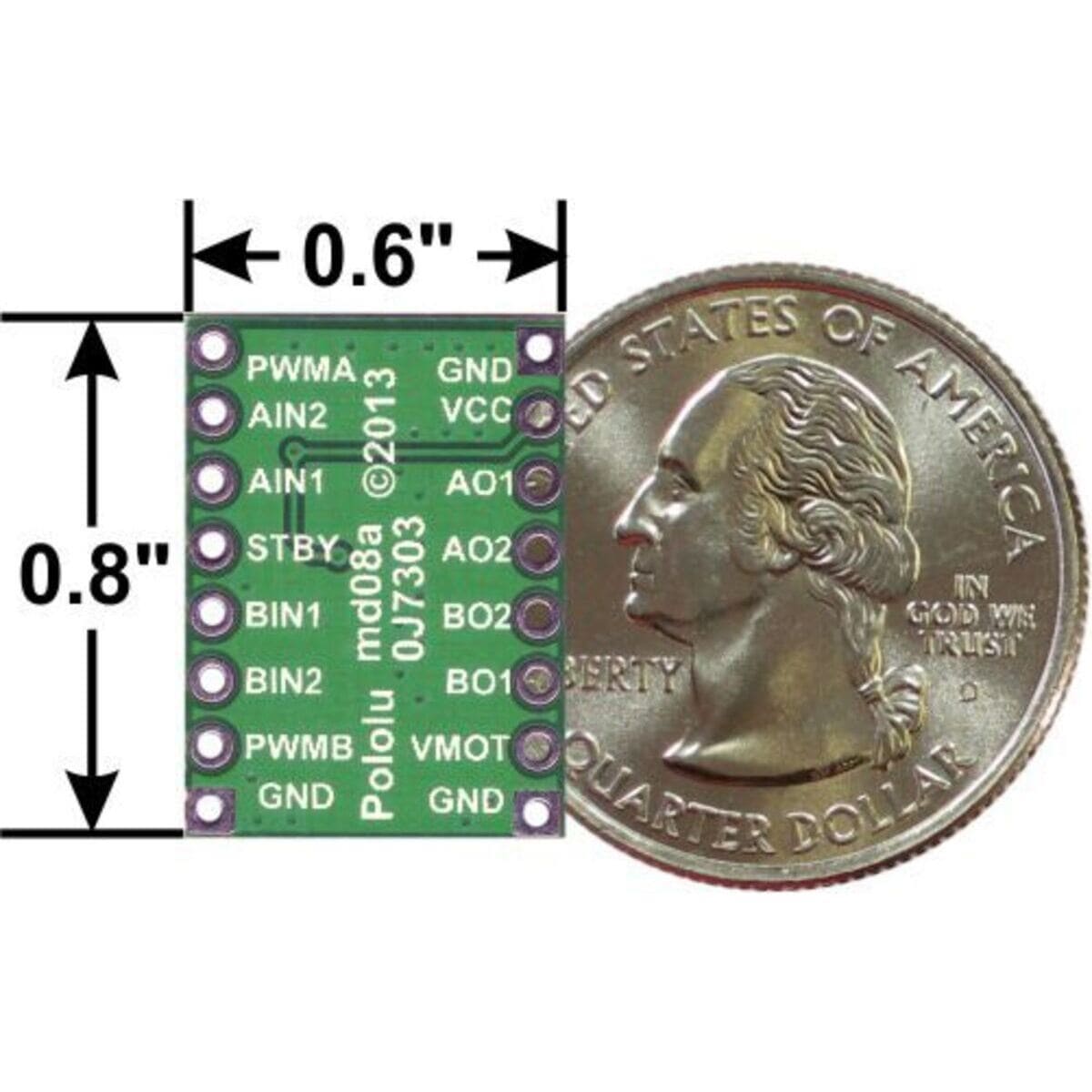

The distance between the header rows on the PCB is 0.1" smaller than a standard 0.6" DIP package (e.g. the Baby Orangutan), but the pin spacing allows it to conveniently fit in 0.1" breadboards and perfboards.

For a more advanced motor controller based on this driver, please consider the qik 2s9v1 dual serial motor controller. For a similar motor driver that is easy to use with Arduinos, consider our DRV8835 dual motor driver shield.

| Motor driver | TB6612FNG |

| Motor channels | 2 |

| Minimum operating voltage | 4.5V |

| Maximum operating voltage | 13.5V |

| Continuous output current per channel | 1A |

| Peak output current per channel | 3A |

| Continuous paralleled output current | 2A |

| Maximum PWM frequency | 100 kHz |

| Minimum logic voltage | 2.7V |

| Maximum logic voltage | 5.5V |

| Reverse voltage protection? | Y |

| Size | 0.60" x 0.80" |

| Weight | 1.5 g |

The TB6612 motor driver used on the carrier board has a peak current rating of 3 A per channel.

The peak ratings are for quick transients (e.g. when a motor is first turned on), and the continuous rating of 1 A is dependent on various conditions, such as the ambient temperature. The actual current you can deliver will depend on how well you can keep the motor driver cool. The carrier’s printed circuit board is designed to draw heat out of the motor driver chip, but performance can be improved by adding a heat sink.

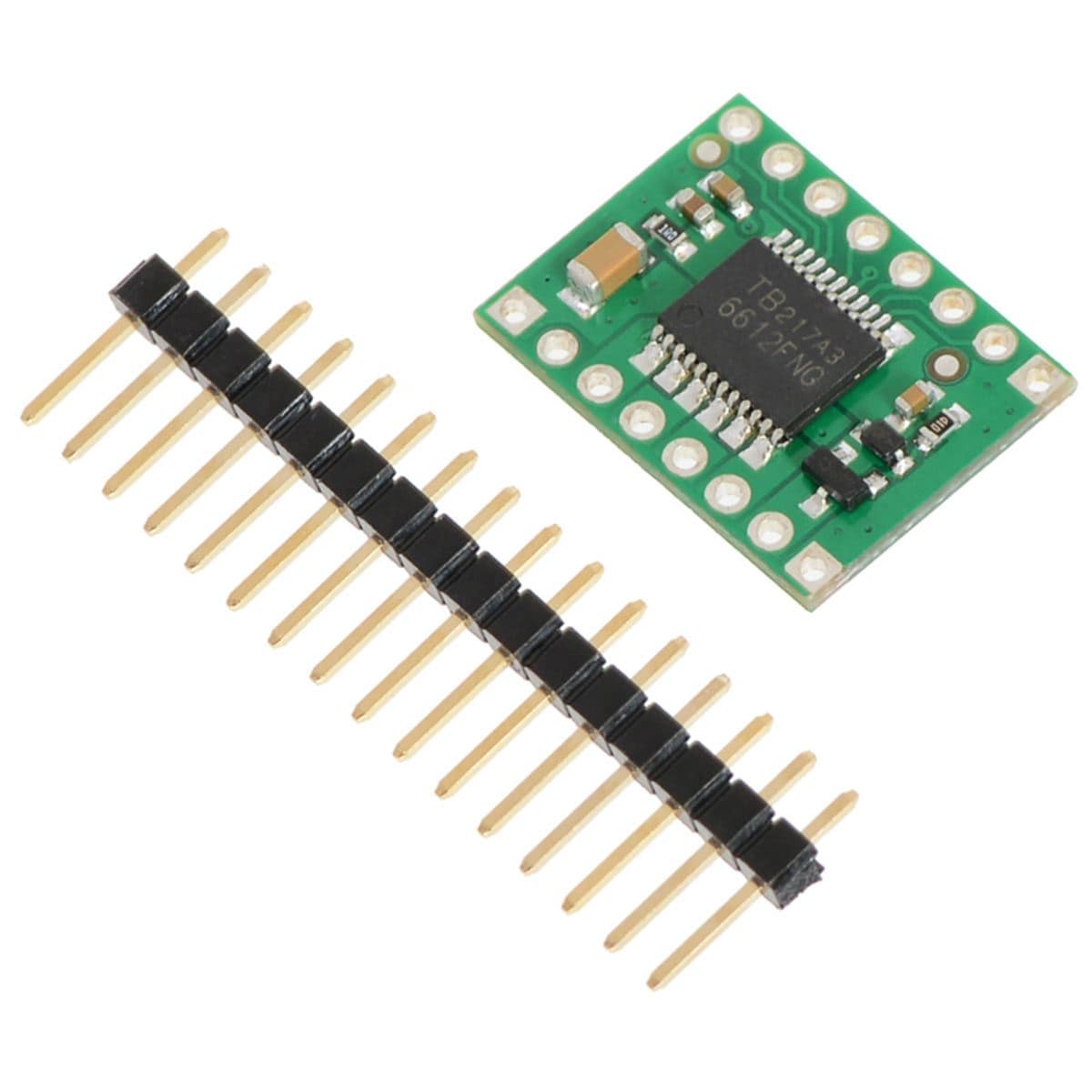

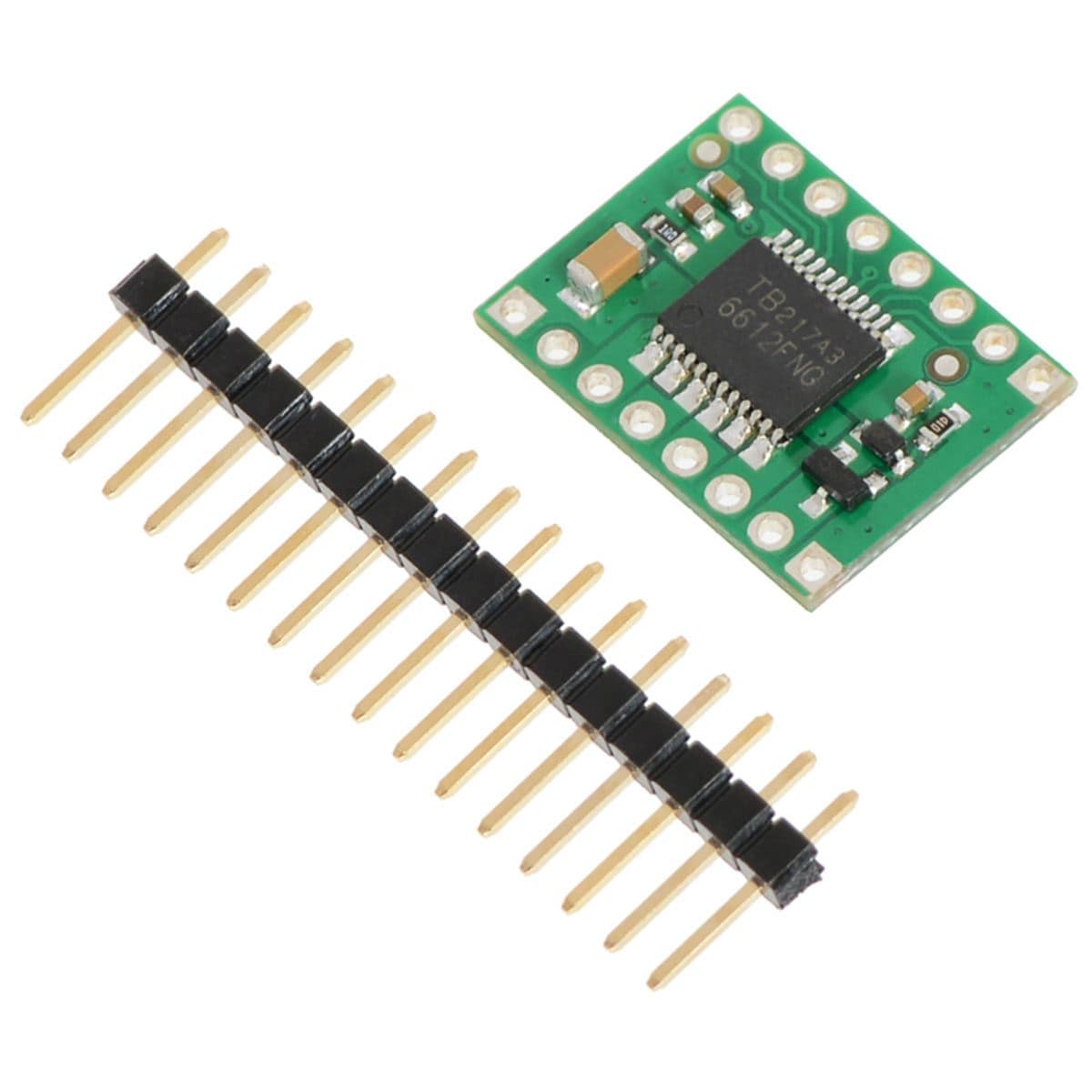

A 1×16-pin breakaway 0.1″ male header strip is included with the TB6612FNG motor driver carrier. This strip can optionally be soldered to the carrier board so that it can be used with perfboards, solderless breadboards, or 0.1″ female connectors. (The headers might ship as two 1×8 pieces or as a single 1×16 piece that can be broken in half.)