Login / Signup

Cart

Your cart is empty

The LSM6DSO combines a digital 3-axis accelerometer and 3-axis gyroscope into a single package. The sensor provides six independent acceleration and rotation rate readings whose sensitivities can be set in the ranges of ±2 g to ±16 g and ±125°/s to ±2000°/s, available through I²C/I3C and SPI interfaces.

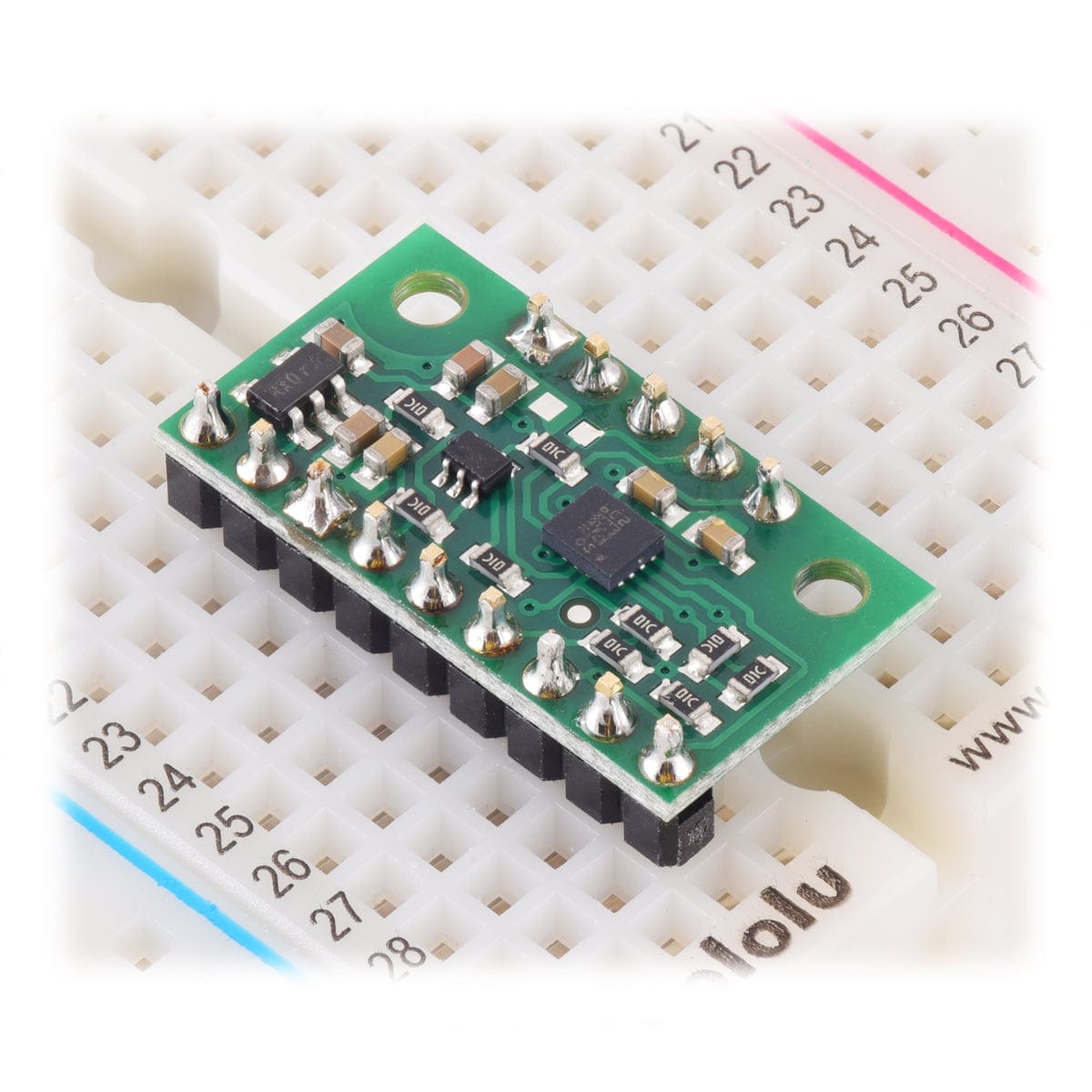

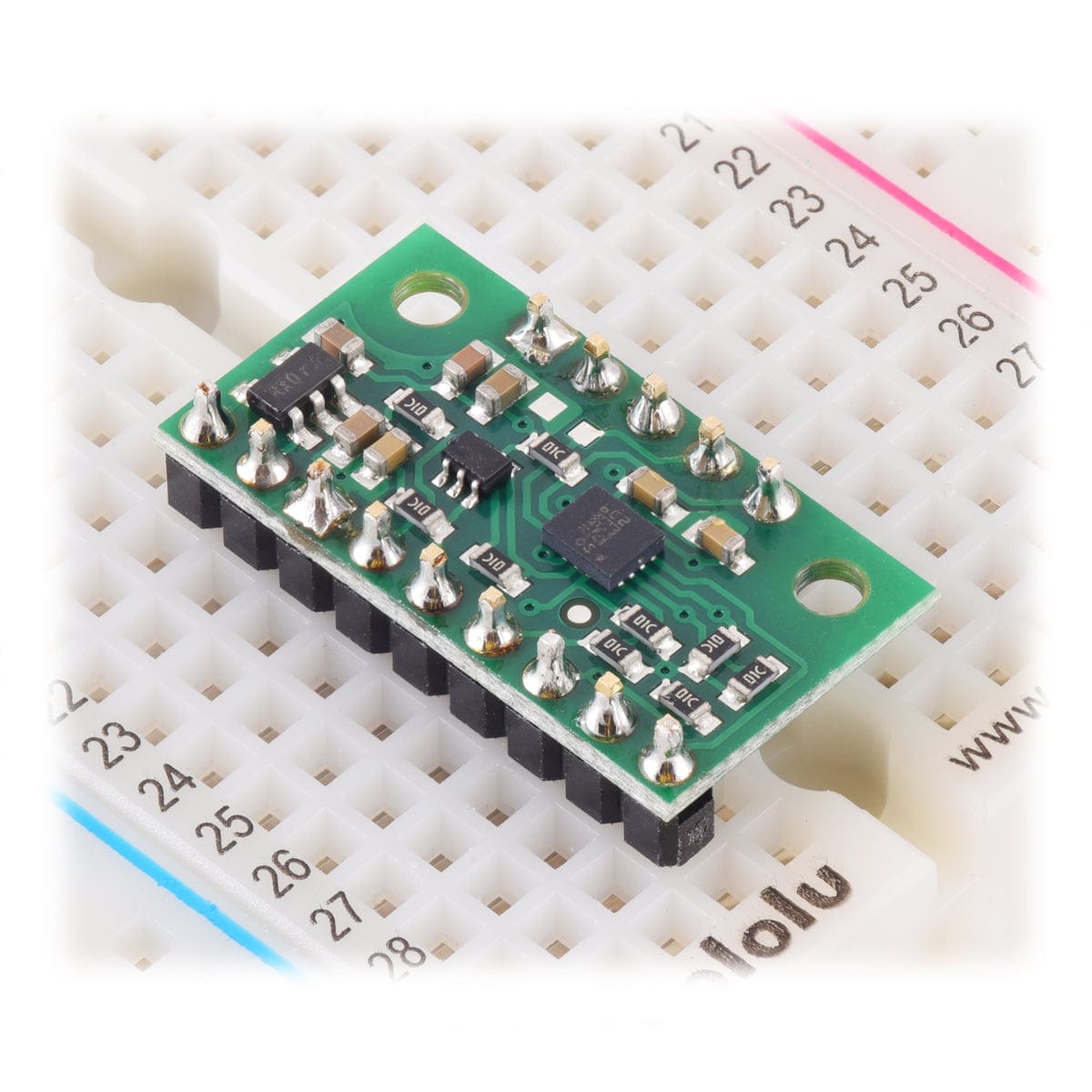

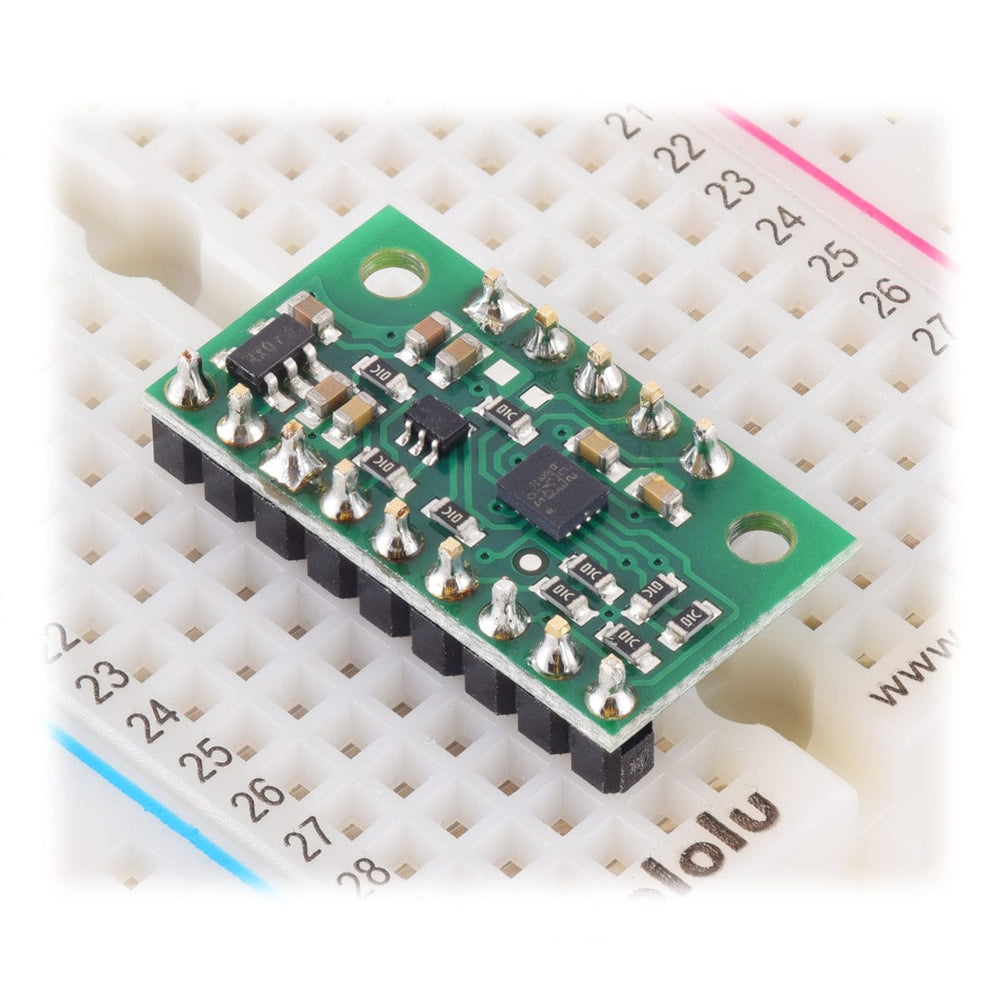

This Pololu LSM6DSO carrier board includes a 3.3 V voltage regulator and integrated level shifters that allow operation from 1.8 V to 5.5 V, and the 0.1″ pin spacing makes it easy to use with standard solderless breadboards and 0.1″ perfboards.

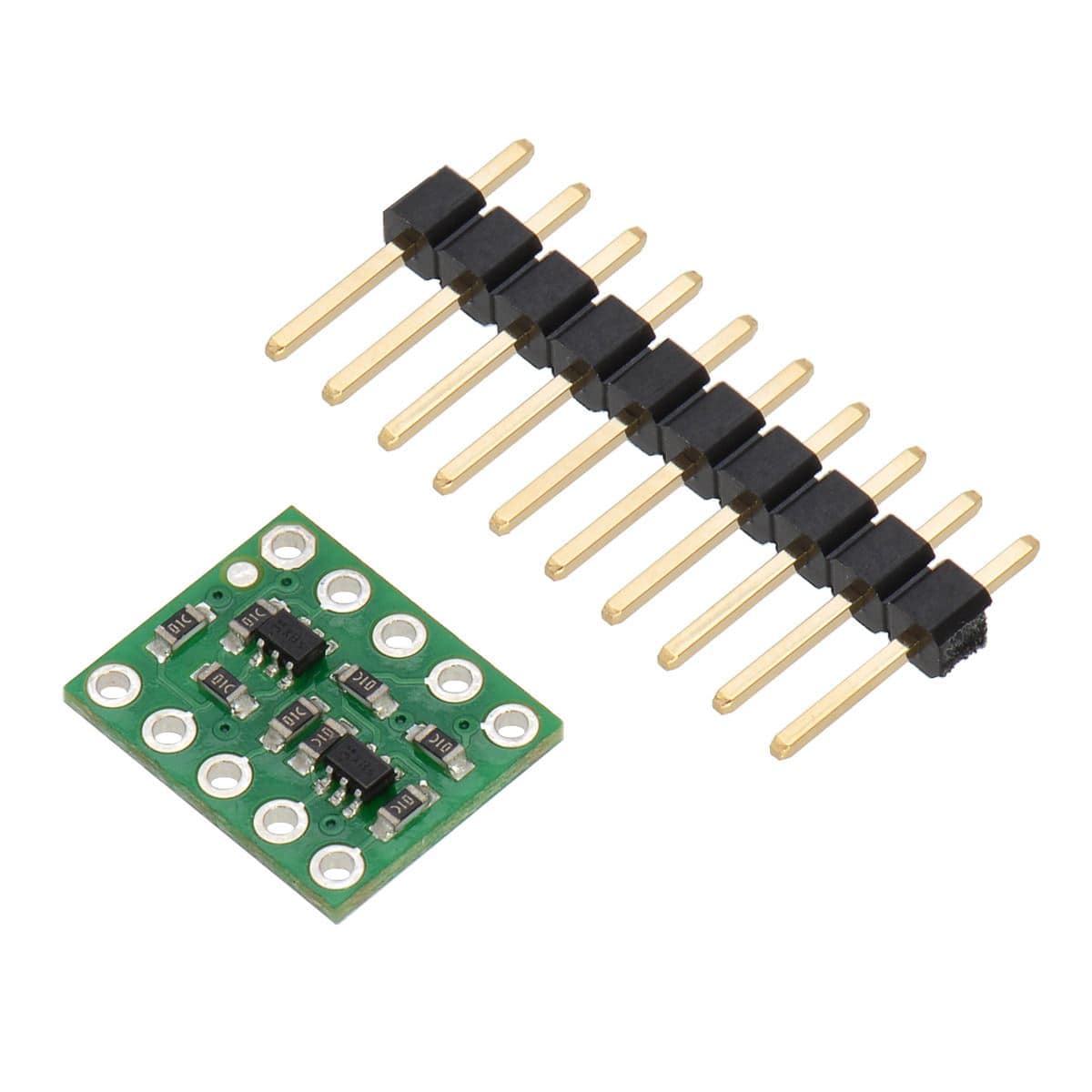

Pin headers not included

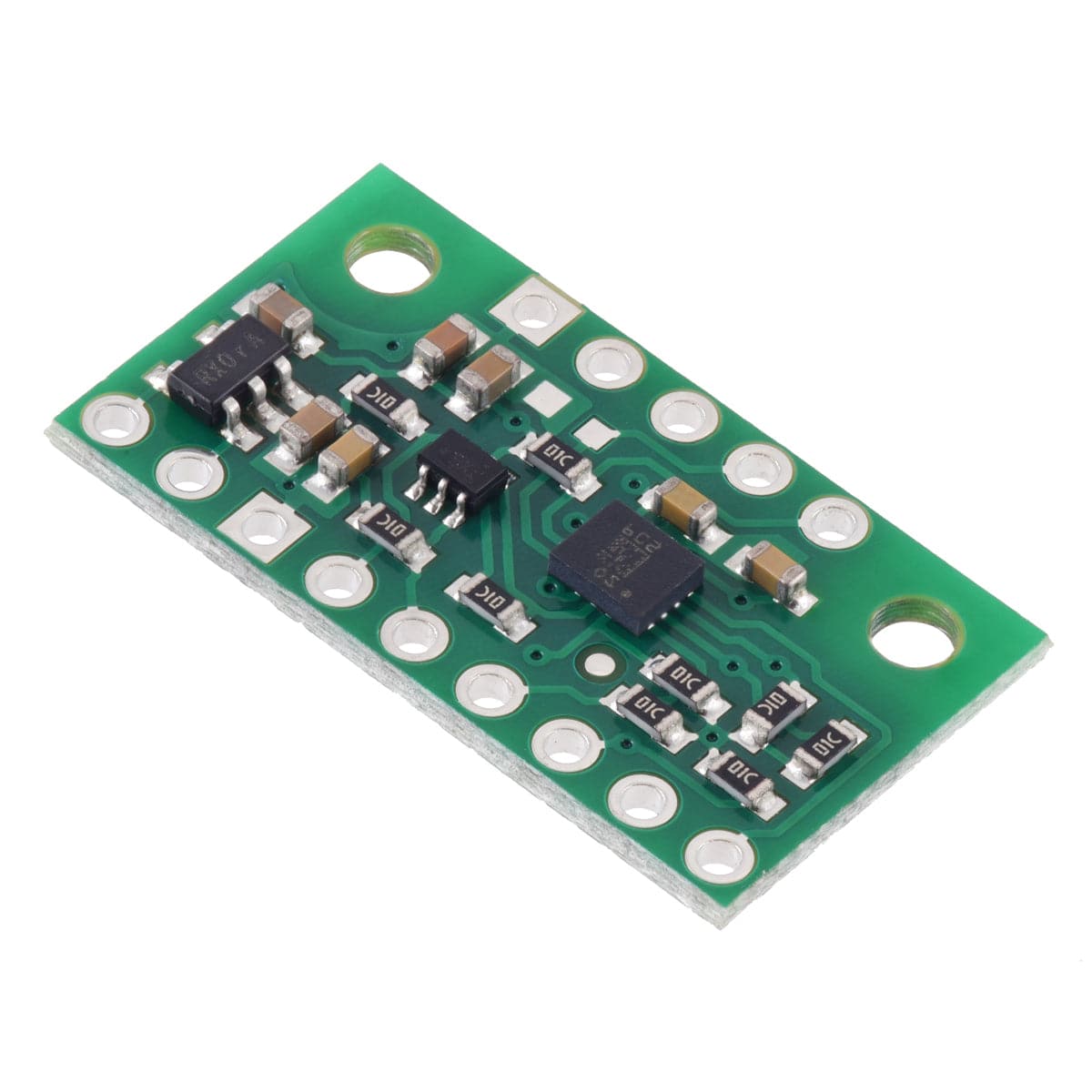

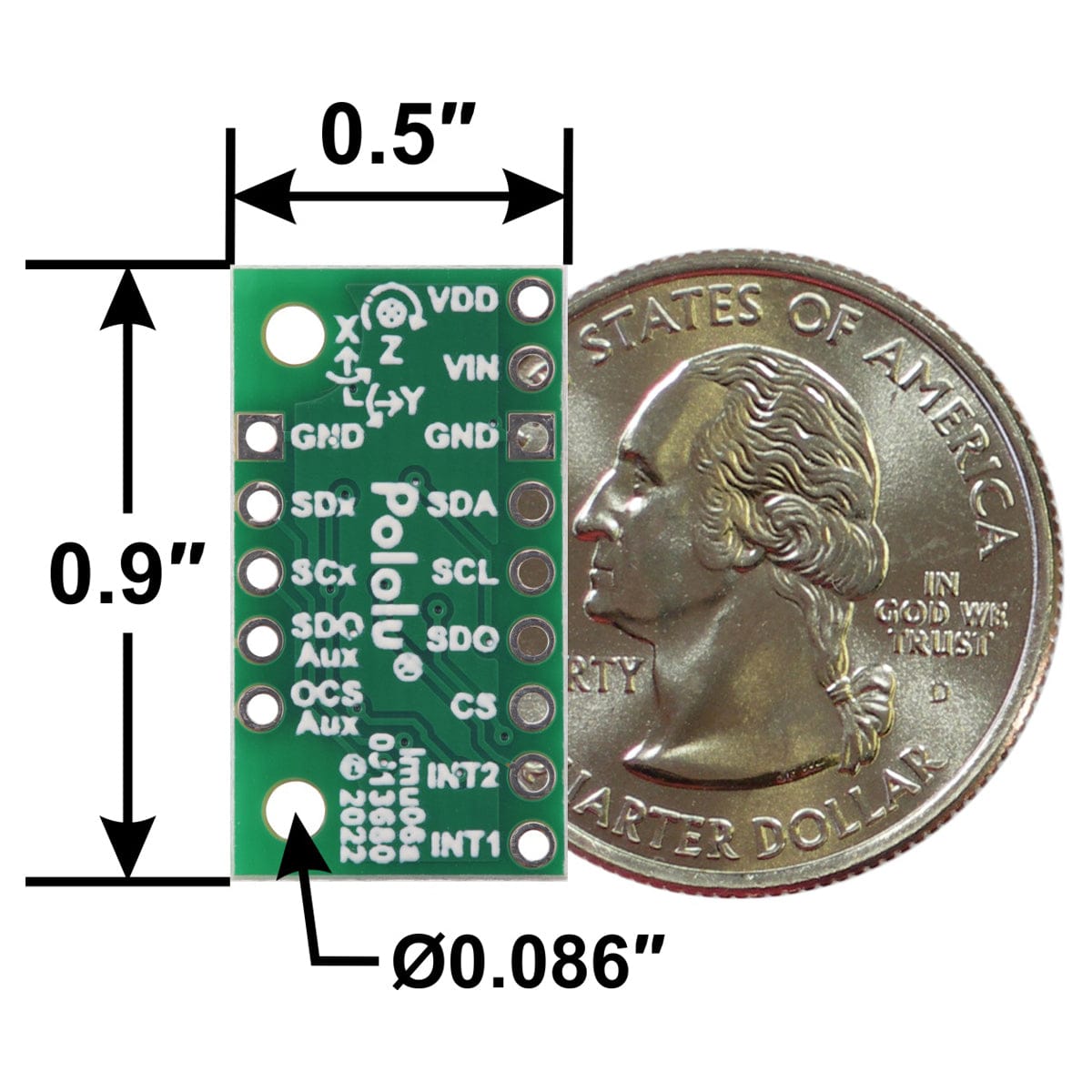

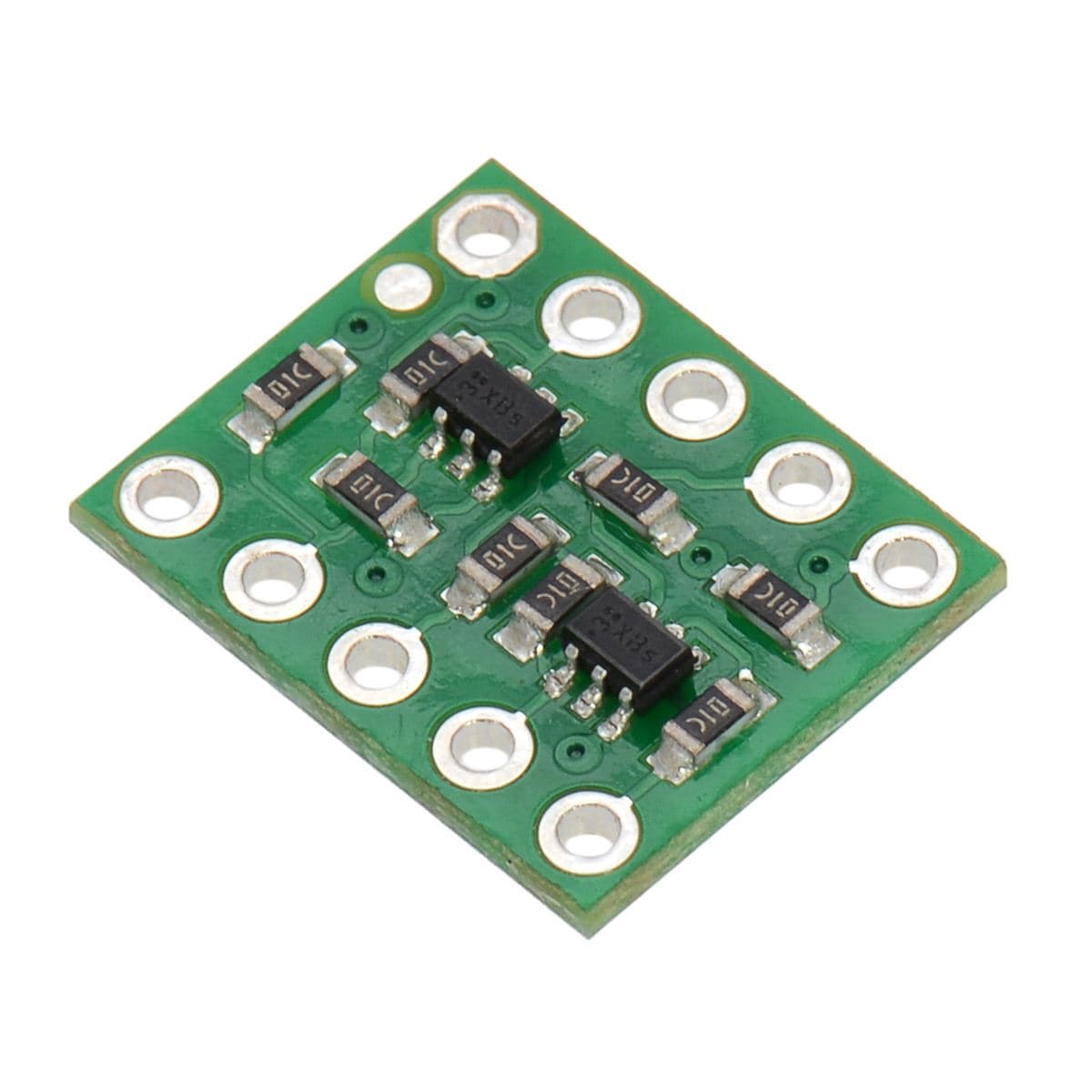

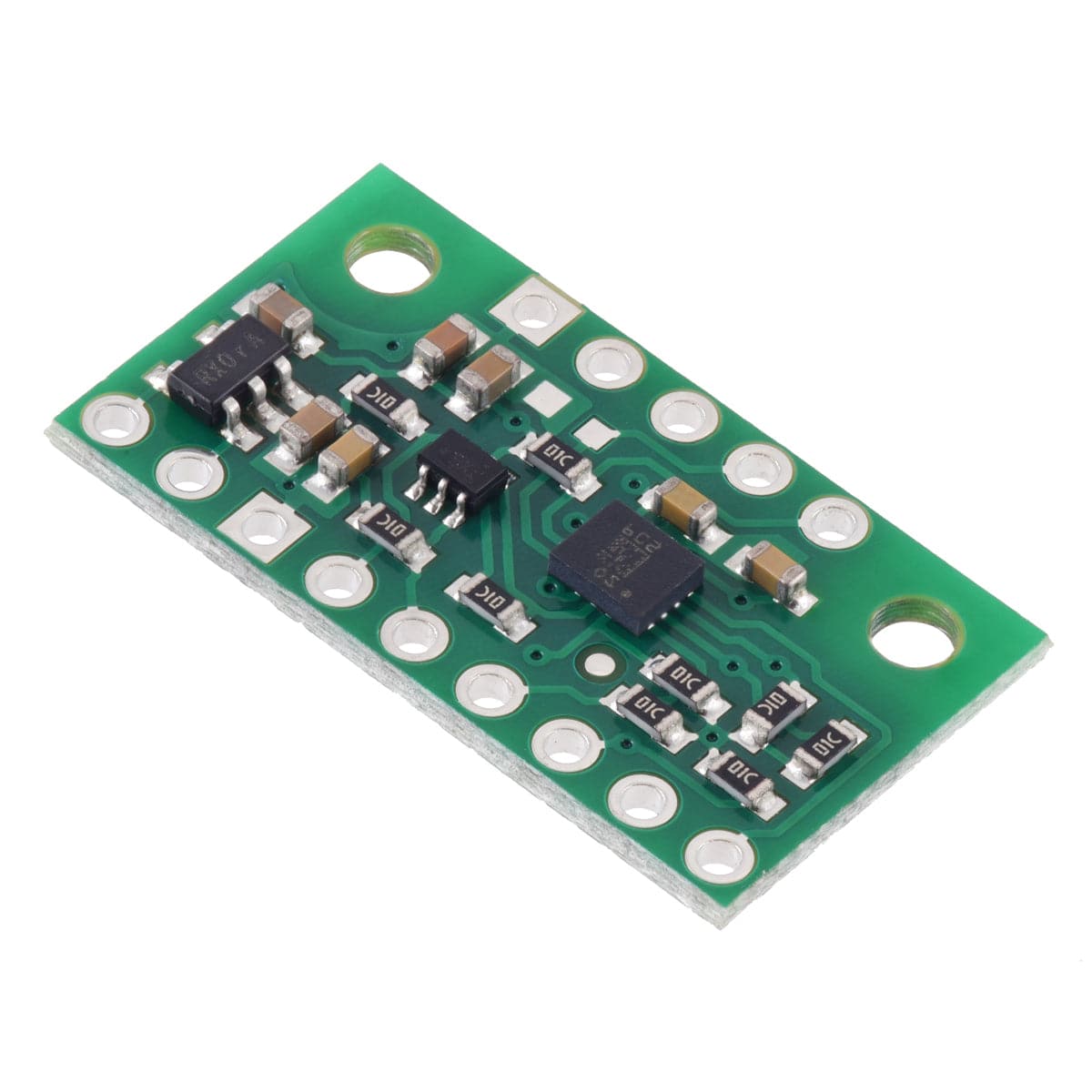

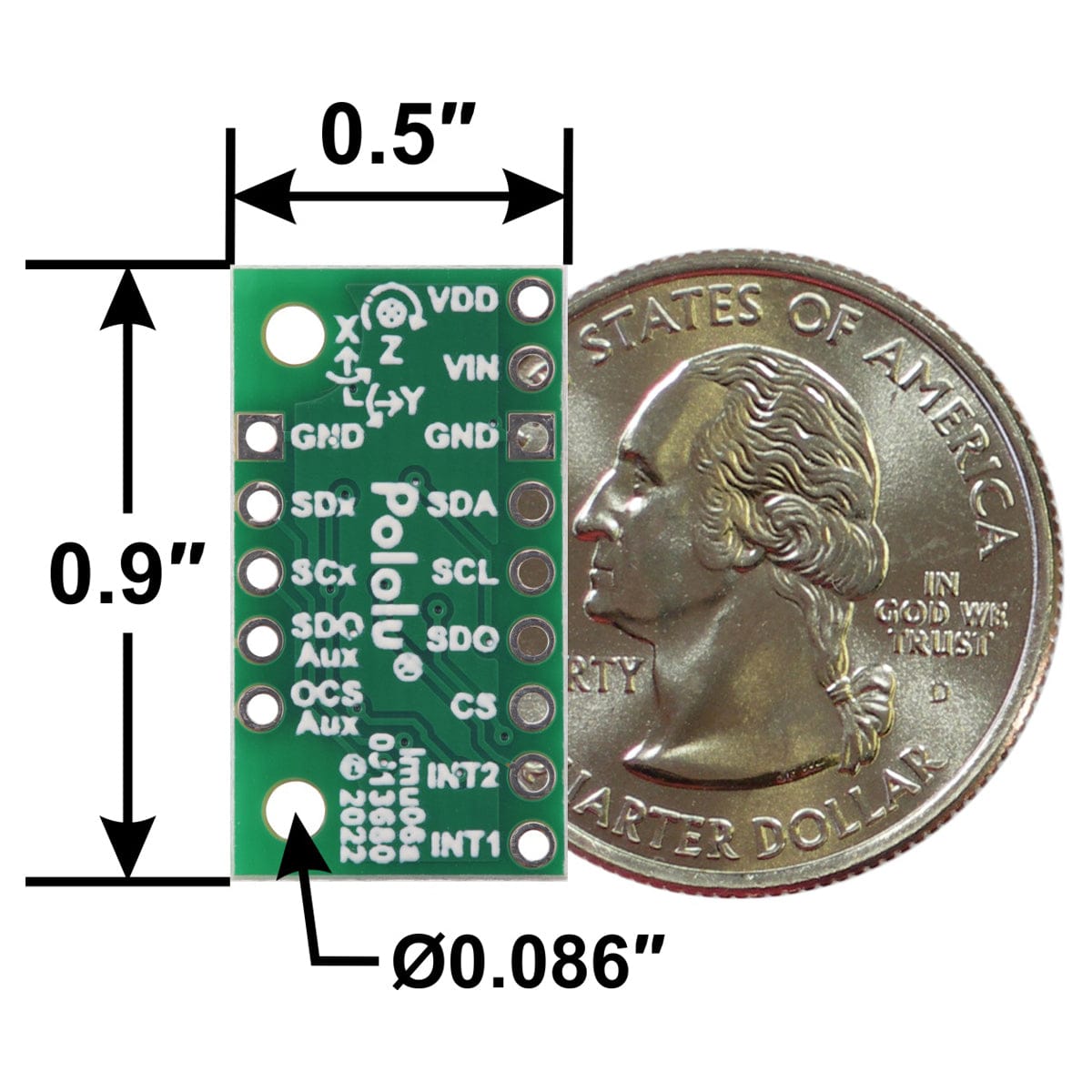

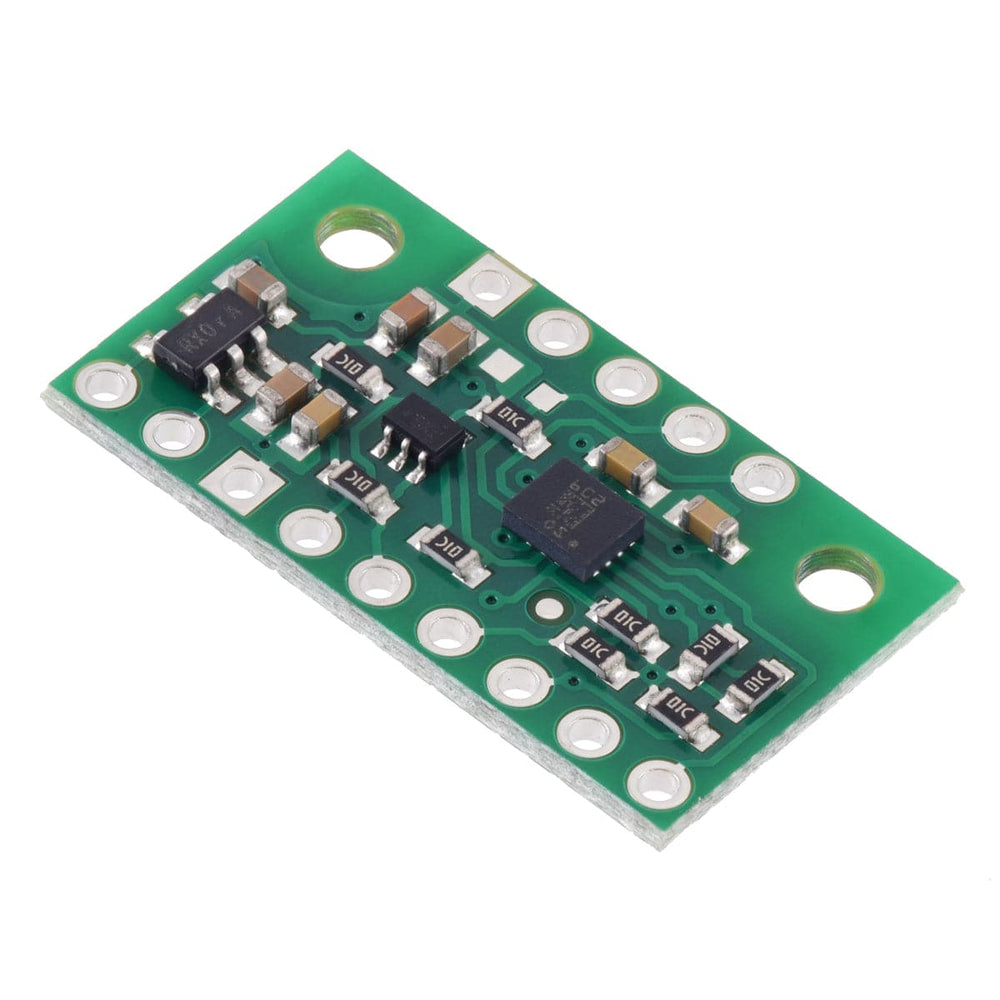

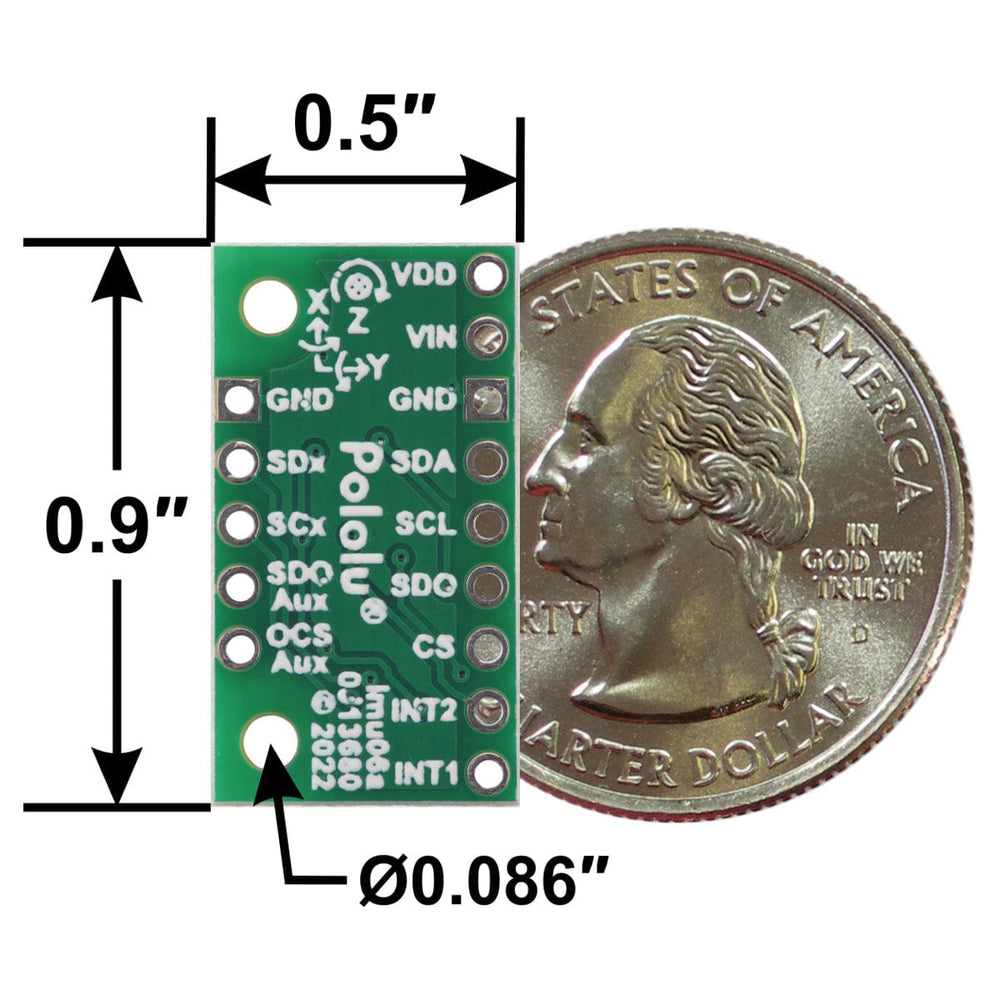

This board is a compact (0.5″ × 0.9″) breakout board for ST’s LSM6DSO inertial module, which features a 3-axis digital linear accelerometer and 3-axis digital rate gyroscope; we therefore recommend careful reading of the LSM6DSO datasheet before using this product. The LSM6DSO is a great IC, but its small package makes it difficult for the typical student or hobbyist to use. It also operates at voltages below 3.6 V, which can make interfacing difficult for microcontrollers operating at 5 V. This carrier board addresses these issues by incorporating additional electronics, including a 3.3 V voltage regulator and level-shifting circuits, while keeping the overall size as compact as possible. The board ships fully populated with its SMD components, including the LSM6DSO, as shown in the product picture.

The LSM6DSO inertial measurement unit (IMU) has many configurable options, including dynamically selectable sensitivities for the accelerometer and gyro, a choice of output data rates, and two independently-programmable external inertial interrupt pins. The accelerometer and gyro can be individually turned on and off to save power. The sensor can be configured and its readings can be accessed through a digital interface, which can be configured to operate in either I²C (TWI) or SPI mode. The MIPI I3C protocol is also supported on the I²C pins.

The six independent acceleration and angular rate readings (sometimes called 6DOF) provide data that a microcontroller or computer can use to calculate the orientation of the LSM6DSO on two axes (roll and pitch; a magnetometer is generally required to compute yaw accurately). With an appropriate algorithm, the gyro can be used to very accurately track rotation on a short timescale, while the accelerometer can help compensate for gyro drift over time by providing an absolute frame of reference.

The carrier board includes a low-dropout linear voltage regulator that provides the 3.3 V required by the LSM6DSO, which allows the sensor to be powered from a 1.8 V to to 5.5 V. The regulator output is available on the VDD pin and can supply almost 150 mA to external devices. The breakout board also includes a circuit that shifts the I²C clock and data lines to the same logic voltage level as the supplied VIN, making it simple to interface the board with 5 V systems. The pins are spaced to work with standard 0.1″ (2.54 mm) male headers and 0.1″ female headers (available separately), making the board easy to use with solderless breadboards and 0.1″ perfboards. The board has two mounting holes that work with #2 and M2 screws (not included).

Compared to the LSM6DS33, the LSM6DSO offers various improvements like lower noise and a higher maximum output data rate for the gyro. In addition to standard operation as an I²C or SPI slave (Mode 1), the LSM6DSO also supports additional specialized modes with a secondary interface: it can act as a master (sensor hub) on a second I²C bus (Mode 2), or it can provide an auxiliary SPI slave interface that is useful for electronic and optical image stabilization (EIS/OIS) applications (Mode 3/4). See the datasheet and application note for more information about these modes. Our carrier board brings out these secondary interface pins on the side opposite the main connections.

This LSM6DSO carrier is pin-compatible with our earlier LSM6DS33 carrier (and many of our other ST I²C/SPI sensor carriers), and the orientation of the sensor axes is the same. The ICs also use the same I²C address and have similar register interfaces, so code written to interface with the LSM6DS33 can probably be modified to work with an LSM6DSO without too much trouble.

Regardless of the interface being used to communicate with the LSM6DSO, its VIN pin should be connected to a 1.8 V to 5.5 V source, and GND should be connected to 0 volts. (Alternatively, if you are using the board with a logic voltage of 3.3 V or lower, you can leave VIN disconnected and bypass the built-in regulator by connecting the logic supply directly to VDD.)

A minimum of two logic connections is necessary to use the LSM6DSO in I²C mode (this is the default mode): SCL and SDA. These pins are connected to built-in level-shifters that make them safe to use at voltages over 3.3 V; they should be connected to an I²C bus operating at the same logic level as VIN. The remaining pins are not connected to level-shifters on the board and are not 5V-tolerant, but our 4-channel bidirectional logic level shifter can be used externally with those pins to achieve the same effect.

To use the LSM6DSO in SPI mode, four logic connections are typically used: SPC, SDI, SDO, and CS. These should be connected to an SPI bus operating at the same logic level as VIN. The SPI interface operates in 4-wire mode by default, with SDI and SDO on separate pins, but it can be configured to use 3-wire mode so that SDO shares a pin with SDI.

| Pin | Description |

| VDD | Regulated 3.3 V output. Almost 150 mA is available to power external components. (If you want to bypass the internal regulator, you can instead use this pin as a 1.8 V to 3.3 V input with VIN disconnected.) |

| VIN | This is the main 1.8 V to 5.5 V power supply connection. The SCL/SPC and SDA/SDI level shifters pull the I²C and SPI bus high bits up to this level. |

| GND | The ground (0 V) connection for your power supply. Your I²C or SPI control source (and any devices connected to the secondary interface) must also share a common ground with this board. |

| SDA/SDI/SDO | Level-shifted I²C/I3C data line and SPI data in line (also doubles as SDO in 3-wire mode): HIGH is VIN, LOW is 0 V |

| SCL/SPC | Level-shifted I²C/I3C/SPI clock line: HIGH is VIN, LOW is 0 V |

| SDO/SA0 | SPI data out line in 4-wire mode: HIGH is VDD, LOW is 0 V. Also used as an input to determine I²C slave address (see below). This I/O is not level-shifted. |

| CS | SPI enable (chip select). Pulled up to VDD to enable I²C communication by default; drive low to begin SPI communication. This input is not level-shifted. |

| INT2/DEN | Programmable interrupt, a 3.3-V-logic-level output. Can also be used as a data enable trigger input or, in Mode 2, a sensor hub data ready input (MDRDY). This I/O is not level-shifted. |

| INT1 | Programmable interrupt, a 3.3-V-logic-level output. This output is not level-shifted. |

| SDx | Mode 2: I²C master data line (MSDA) |

| Mode 3/4: Auxiliary SPI data in line (SDI) (also doubles as auxiliary SDO in 3-wire mode) | |

| This I/O is not level-shifted. | |

| SCx | Mode 2: I²C master clock line (MSCL) |

| Mode 3/4: Auxiliary SPI clock line (SCK) | |

| This I/O is not level-shifted. | |

| SDO_Aux | Mode 3/4: Auxiliary SPI data out line in 4-wire mode This output is not level-shifted. |

| OCS_Aux | Mode 3/4: Auxiliary SPI enable (chip select); pulled up by default. |

| This input is not level-shifted. |

With the CS pin in its default state (pulled up to VDD), the LSM6DSO can be configured and its readings can be queried through the I²C bus. Level shifters on the I²C clock (SCL) and data lines (SDA) enable I²C communication with microcontrollers operating at the same voltage as VIN (1.8-5.5V). A detailed explanation of the protocol can be found in the LSM6DSO datasheet, and more detailed information about I²C in general can be found in NXP’s I²C-bus specification.

In I²C mode, the sensor’s 7-bit slave (target) address has its least significant bit (LSb) determined by the voltage on the SA0 pin. The carrier board pulls SA0 to VDD through a 10 kΩ resistor, making the LSb 1 and setting the slave address to 1101011b by default. If the selected slave address happens to conflict with some other device on your I²C bus, or if you want to use two LSM6DSO sensors on the same bus, you can drive SA0 low to set the LSb to 0 (which sets the slave address to 1101010b).

The I²C interface on the LSM6DSO is compliant with the I²C fast mode (400 kHz) standard, and the sensor also supports MIPI I3C communication through the same pins.

To communicate with the LSM6DSO in SPI mode, the CS pin (which the board pulls to VDD through a 10 kΩ resistor) must be driven low before the start of an SPI command and allowed to return high after the end of the command. Level shifters on the SPI clock (SPC) and data in (SDI) lines enable SPI communication with microcontrollers operating at the same voltage as VIN (1.8 V to 5.5 V).

In the default 4-wire mode, the sensor transmits data to the SPI master on a dedicated data out (SDO) line that is not level-shifted. If the SPI interface is configured to use 3-wire mode instead, the SDI line doubles as SDO and is driven by the LSM6DSO when it transmits data to the master. A detailed explanation of the SPI interface on the LSM6DSO can be found in its datasheet.

We have written a basic Arduino library for the LSM6 that makes it easy to interface this sensor with an Arduino or Arduino-compatible board like an A-Star. The library makes it simple to configure the LSM6DSO and read the raw accelerometer and gyro data through I²C.

The datasheet provides all the information you need to use this sensor, but picking out the important details can take some time. Here are some pointers for communicating with and configuring the LSM6DSO that we hope will get you up and running a little bit faster: