Login / Signup

Cart

Your cart is empty

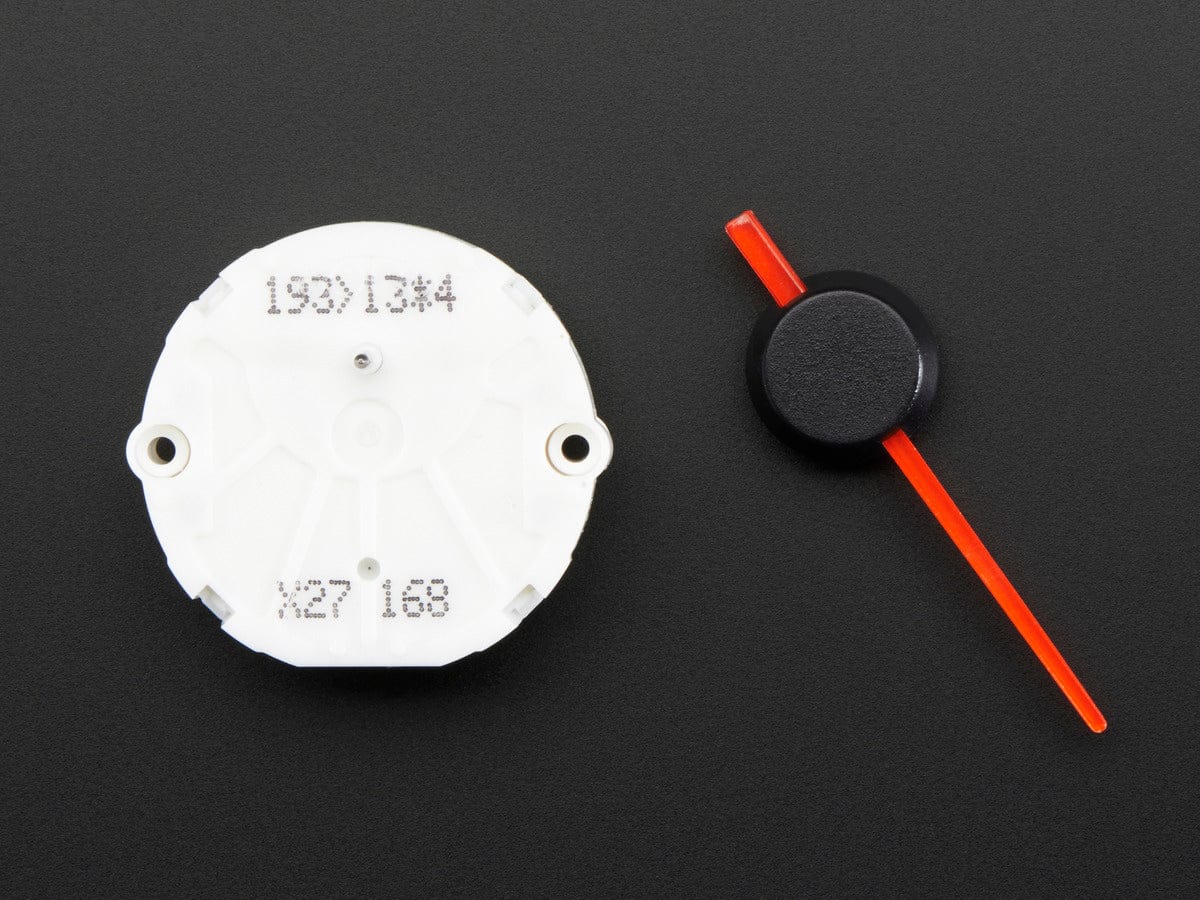

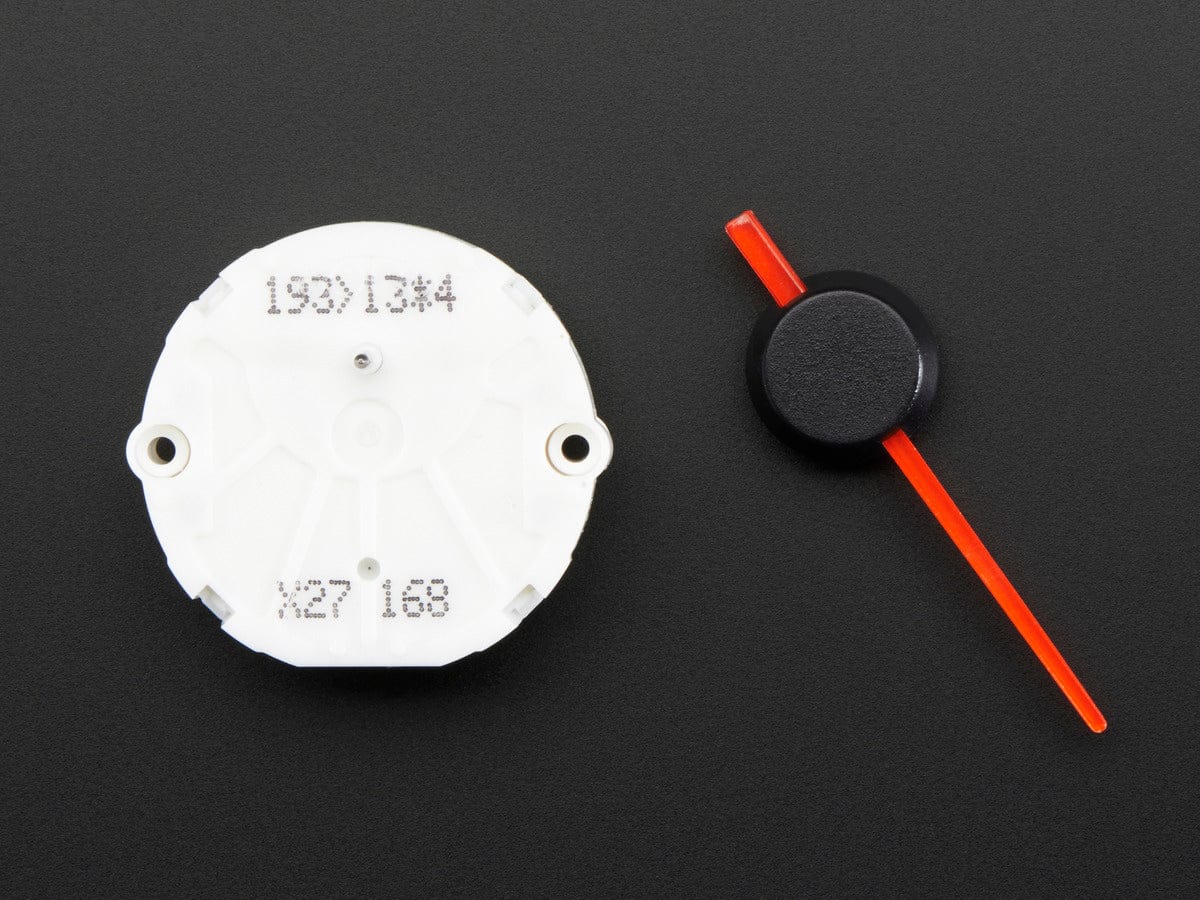

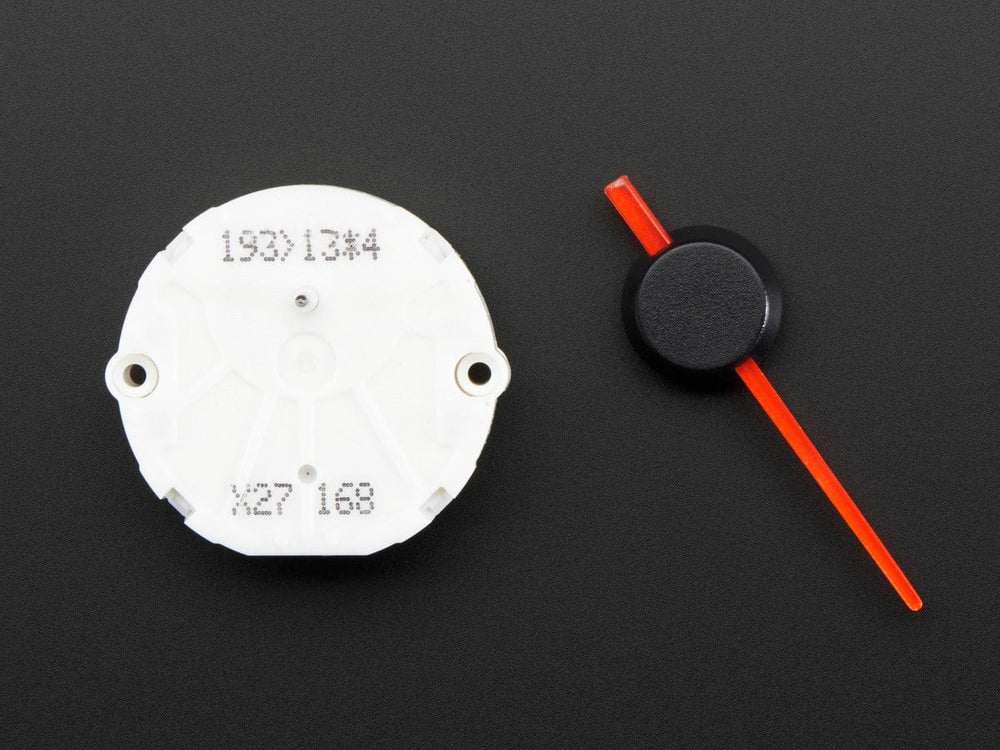

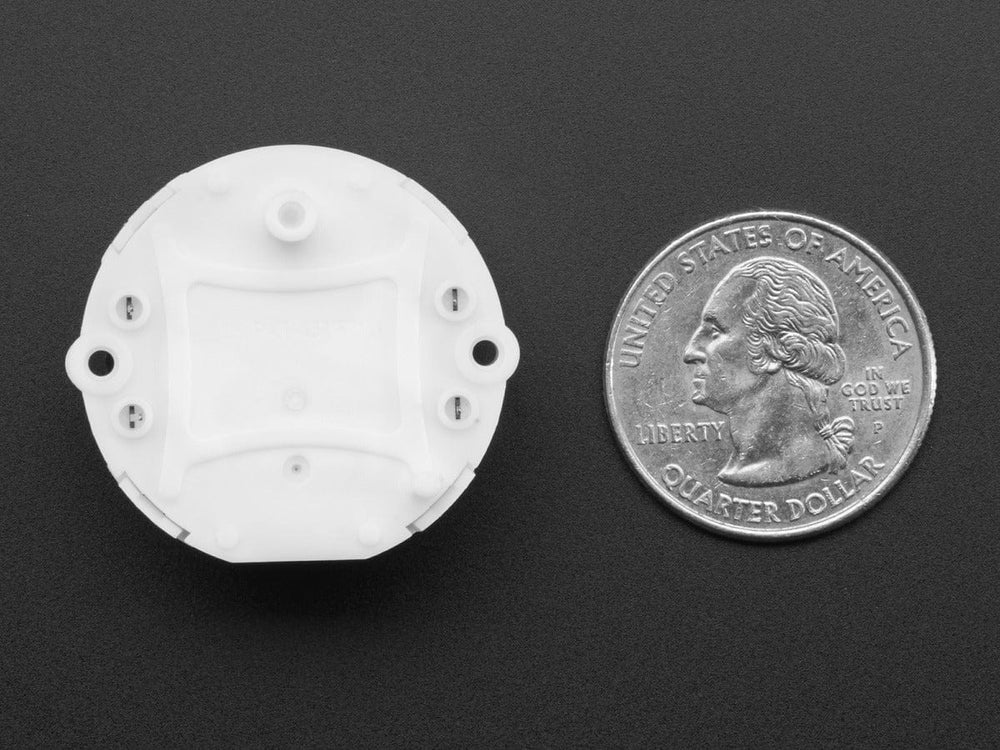

This stepper motor is a little different than the large NEMA-17 types you may be used to. These are often used in gauges for motorcycles and cars to replace the old-style fully-analog type. They have extremely fine step precision of about 1/2 a degree per step, 600 steps for single stepping, fast response for quick movements, and a range of ~315° degrees. Their smooth motion makes good for small projects that need a dial indicator, and more precision motion than you may get with a needle gauge.

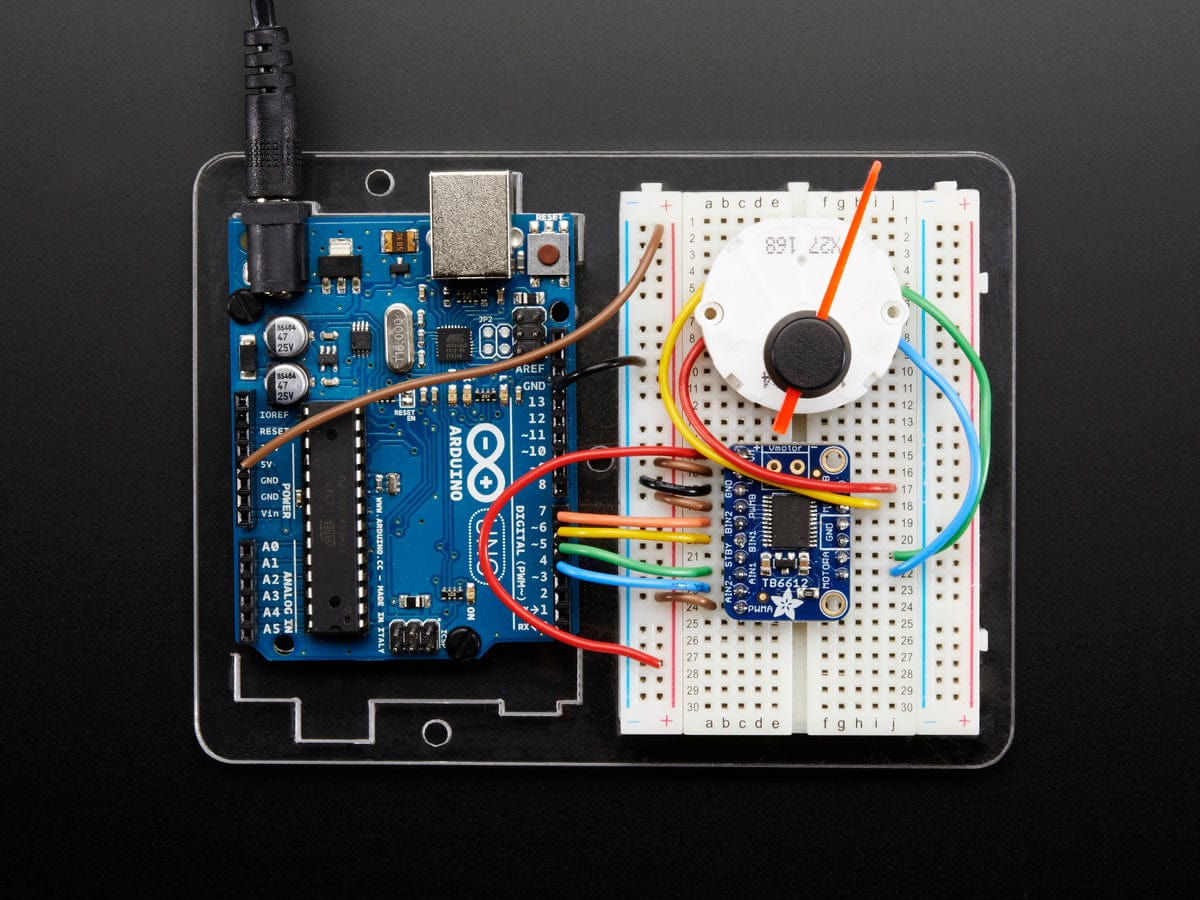

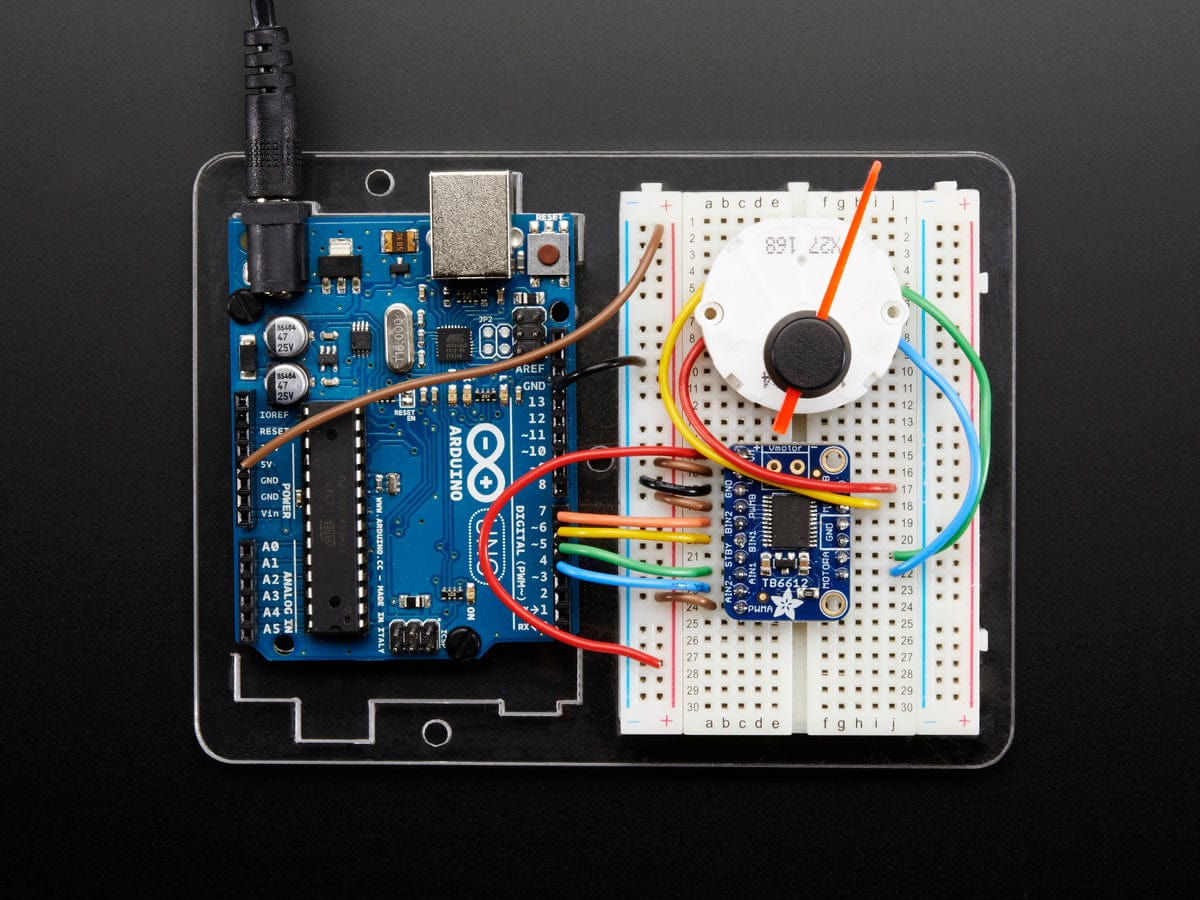

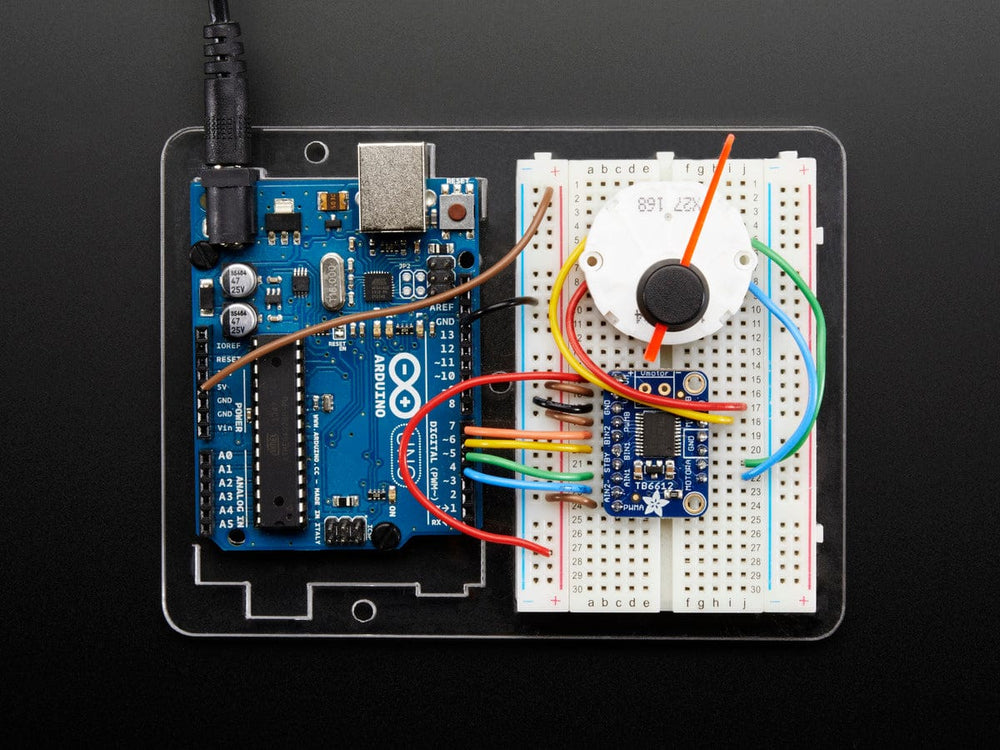

Since this is a bi-polar stepper motor you do need to have some sort of H-Bridge to drive it. A L293D or TB6612 will do the job nicely. If you have a microcontroller that can drive 200 ohm loads you might be able to use the direct pins without extra MOSFETs, just remember to include kickback/flyback protection diodes!

Note that the motor is quite 'weak', not good for moving anything but a light indicator. We include a red-line dial that fits nicely on top by pushing onto the needle shaft.

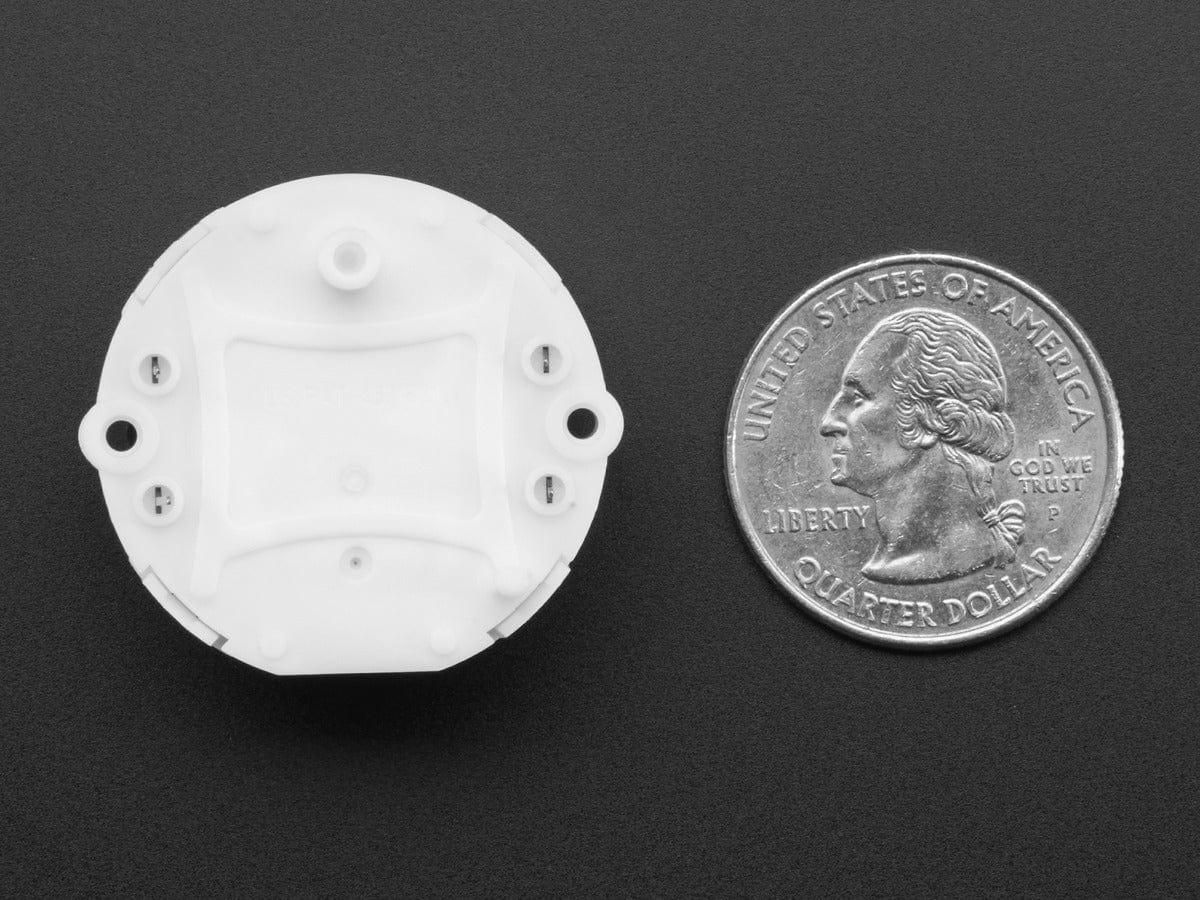

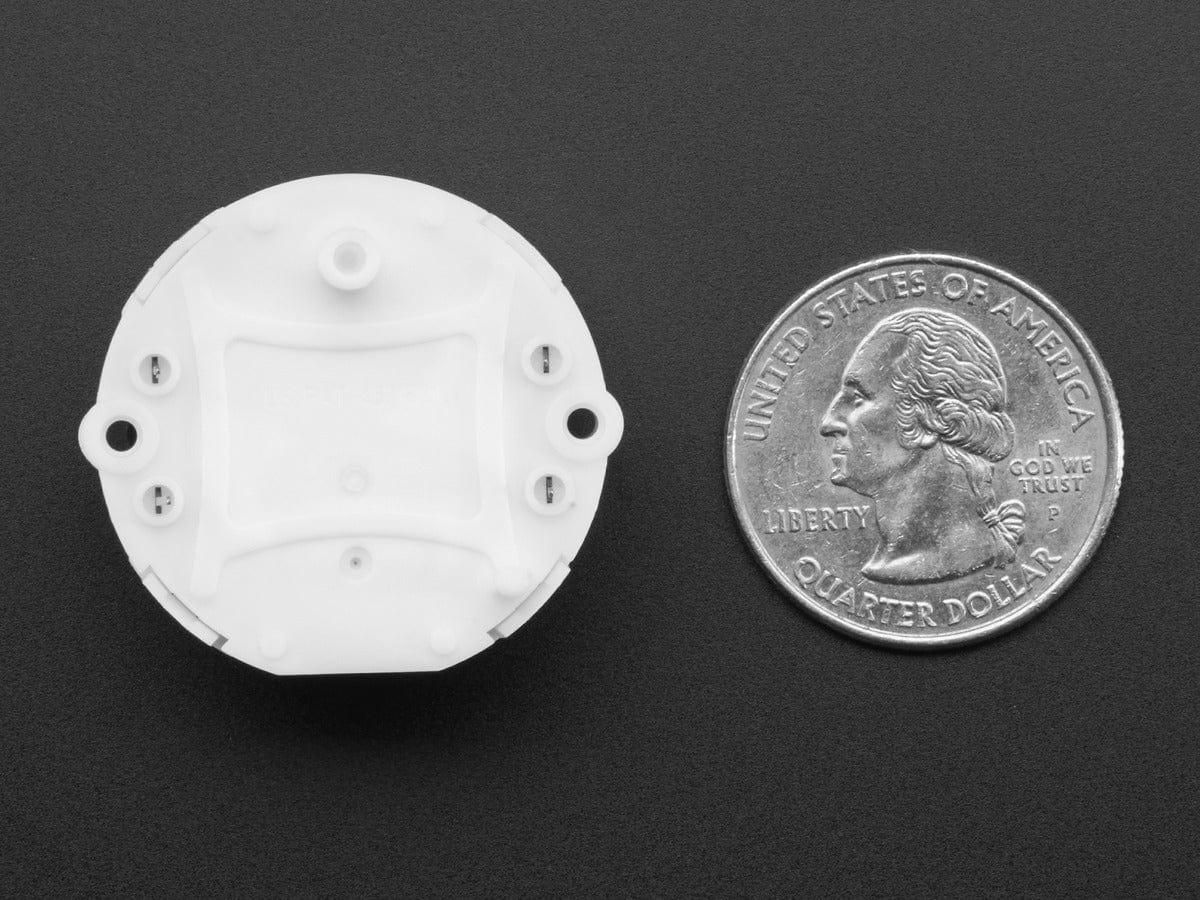

Dimensions: