Login / Signup

Cart

Your cart is empty

Wanna improve the connection strength between your project's 3D-printed parts, and also have nice clean surfaces? Instead of gluing bits together, or screwing plastic screws directly into your 3D prints, use strong and reusable machine screws and heat-set inserts. Heat set inserts are only a few cents a piece and have a grooved outside, with theads on the inside. Originally they were designed for injection molded parts but they work fabulously for 3D printed plastic as well.

If you have tried to set heat-set inserts in your plastic or 3D printed part with your soldering iron, you may have had the frustration of pushing the insert in only to have it come right back out stuck to your soldering iron and ruining your part in the process. Most soldering iron tips can catch on the rim of the insert causing it to stick on the iron when you pull the iron out. If you use the "horizontal method" it's hard to know the insert is straight. These insert tips from Virtjoule have a vertical wall that solves that problem. The iron pulls right out after pressing the hot insert. Because the shoulder is square it's easier to know if the insert is square in the piece, something that's harder to control with a conical soldering tip.

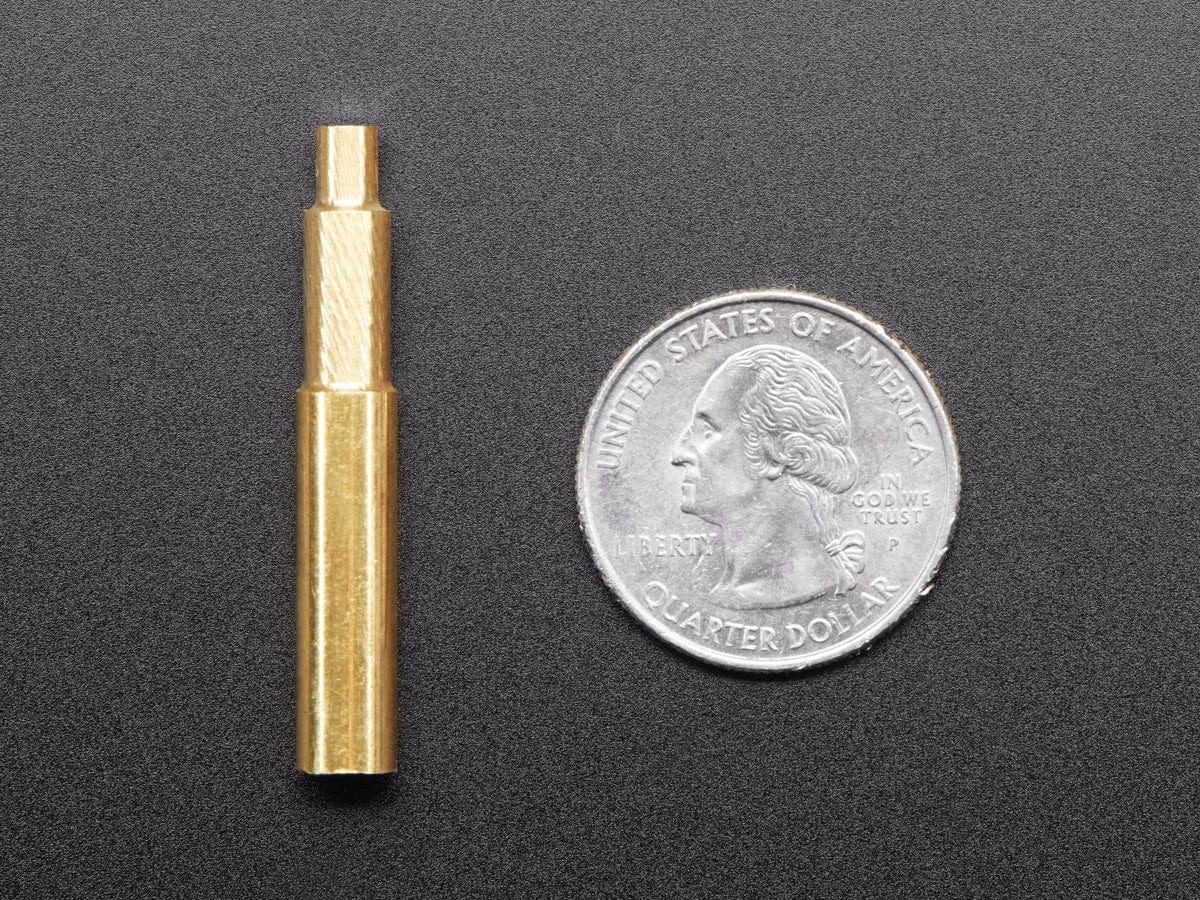

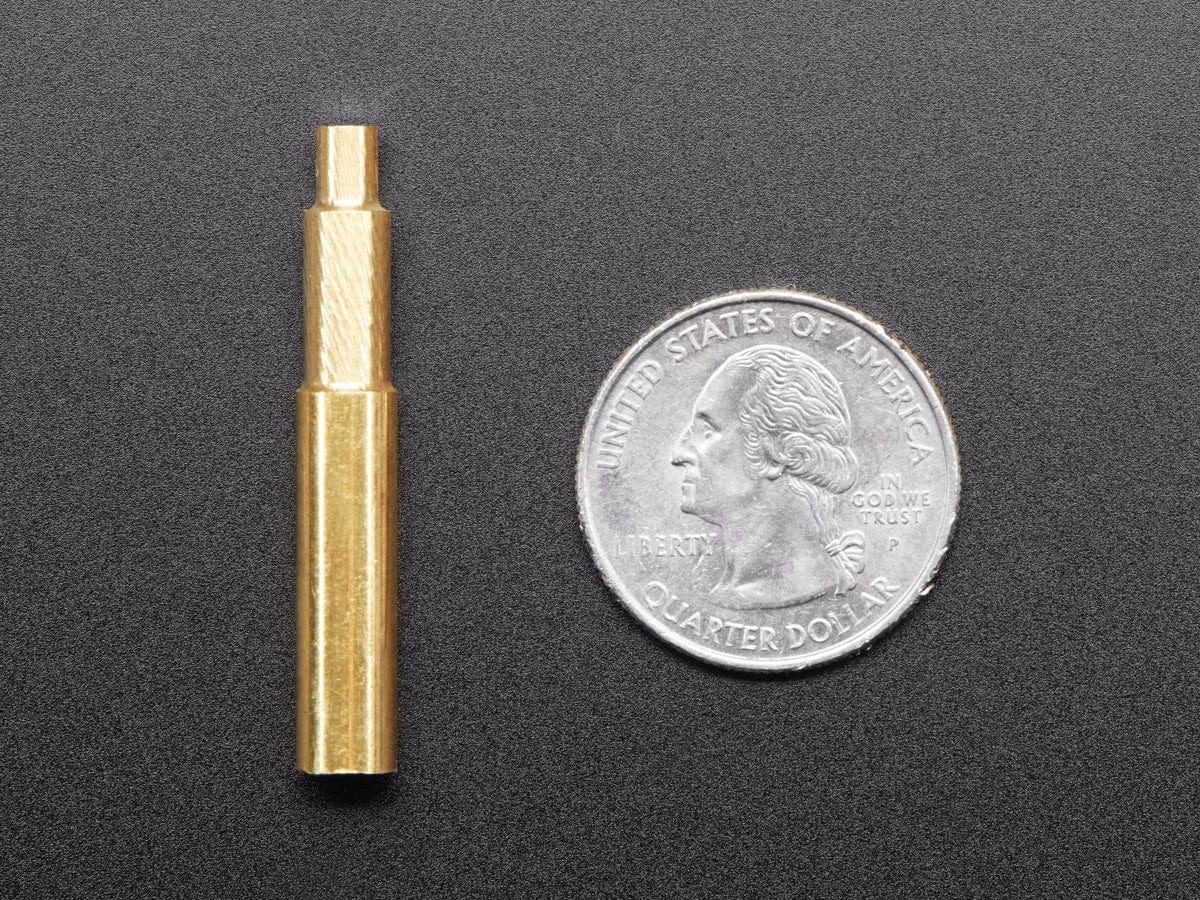

All you need is a soldering iron that takes Hakko tips (which nearly all the irons we stock do). Instead of a soldering tip, attach this specially-turned part. Heat up the iron and use it to press the insert in, wait for it to cool, then use like a hex nut that's embedded inside the plastic.

Check out this video from Noe & Pedro that shows you how to do it

This tip is for use with M5 sized inserts. Soldering iron not included, we have lots you can pick from, any that use Hakko tips will do the job. No inserts are included - you can pick some up at McMaster-Carr.